硅橡胶

一般属性

- 产品等级

- 产品等级(续)

- 产品等级(续)

- 产品等级(续)

| Classification | For general purpose, FDA (21CFR177 2600), BR | JIS B2401 4-C | ||||||||

| Grade | KE-931-U | KE-941-U | KE-951-U | KE-961-U | KE-971-U | KE-981-U | KE-961T-U | KE-971T-U | KE-871C-U | |

| Appearance | Milky white translucent | Grayish white | Miky white translucent | Grayish white | ||||||

| Density 23℃ g/cm³ | 1.07 | 1.11 | 1.14 | 1.22 | 1.3 | 1.42 | 1.17 | 1.2 | 1.29 | |

| Williams plasticity (10 min after remix) | 160 | 190 | 240 | 280 | 330 | 420 | 280 | 340 | 260 | |

| Curing agent | Curing agent name | C-8 | C-8 | C-8 | C-8 | C-8 | C-8 | C-8A | C-8 | C-8 |

| Standard addition quantity*¹ | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 0.5 | 2.0 | 2.0 | |

| Linear shrinkage*² % | 4.0 | 3.9 | 3.9 | 3.4 | 3.0 | 2.7 | 3.6 | 3.4 | 2.9 | |

| Physical strength | Hardness Durometer A | 31 | 43 | 52 | 63 | 71 | 84 | 62 | 71 | 72 |

| Tensile strength MPa | 4.7 | 6.5 | 8.2 | 7.3 | 7.5 | 8.8 | 9.7 | 8.8 | 6.9 | |

| Elongation at break % | 480 | 370 | 330 | 320 | 220 | 100 | 310 | 260 | 190 | |

| Tear strength crescent piece kN/m | 15*³ | 15*³ | 23*³ | 20*³ | 20*³ | 8 | 25*³ | 25*³ | 9 | |

| Compression set 180℃ x 22 h | 15 | 11*4 | 11*4 | 11*4 | 9*4 | 12*4 | 11*4 | 11*4 | 10 | |

| Dielectric breakdown strength Normal state kV | — | 23 | 24 | 25 | 25 | 24 | 24 | 23 | — | |

| Volume resistivity Normal state TΩ.m | — | 7 | 8 | 6 | 3 | 4 | 4 | 4 | — | |

| Classification | Dynamic fatigue durability | Vibration control | For power connector | JIS B2401 4-C | |||||||

| Grade | KE-9551-U | KE-5151-U | KE-5550-U | KE-501EM-U | KE-7211-U | KE-7212-U | KE-7213-U | X-30-3893-U | KE-9590-U | ||

| Appearance | Milky white translucent | Pale yellow | Milky white translucent | Light gray | Gray | Blue-white | Black | Milky white translucent | |||

| Density 23℃ g/cm³ | 1.12 | 1.1 | 1.25 | 1.10 | 1.15 | 1.20 | 1.97 | 1.09 | 1.15 | ||

| Williams plasticity (10 min after remix) | 200 | 170 | 370 | 170 | 220 | 250 | 190 | 290 | 220 | ||

| Curing agent | Curing agent name | C-8A | C-8B | C-8 | C-15 | C-3 | C-3 | C-8 | C-8A | C-8 | |

| Standard addition quantity*¹ | 0.6 | 1.0 | 2.0 | 1.5 | 1.3 | 1.3 | 2.0 | 1.0 | 2.0 | ||

| Linear shrinkage*² % | 3.3 | 3.9 | 5.2 | 3.9 | — | — | — | — | 3.9 | ||

| Physical strength | Hardness Durometer A | 50 | 54 | 52 | 53 | 54 | 58 | 45 | 40 | 51 | |

| Tensile strength MPa | 6.6 | 7.7 | 9.3 | 7.7 | 11.0 | 9.2 | 2.5 | 7.4 | 8.8 | ||

| Elongation at break % | 310 | 450 | 730 | 520 | 780 | 680 | 320 | 680 | 400 | ||

| Tear strength crescent piece kN/m | 6 | 15 | 38 | 19 | 31 | 35 | 8 | 26 | 22*³ | ||

| Compression set 180℃ x 22 h | 20 | 13 | 22 | 9 | 10 | — | 17 | 14*4 | |||

| Dielectric breakdown strength kV | Normal state | — | — | — | — | 28 | 28 | — | — | 22 | |

| Submerged | — | — | — | — | 190 | 100 | 0.1 | — | 0.4 | ||

| Remarks | Middle fatigue durability | High fatigue durability | High decrement | Low motion magnification | Tracking property 3.5 kV | Tracking property 4.5 kV | High dielectricity | Specific resistance 0.2 Ω.M | — | ||

| Measurement: in accordance with JIS K 6249 Test pieces: 160°C x 10 min (press cure), 200°C x 4 h (post cure) | |||||||||||

| ✽1 Standard addition quantity is the quantity of the curing agent added to 100 parts compound | |||||||||||

| ✽2 Linear shrinkage calues differ according to the curing agent used | |||||||||||

| ✽3 Angle piece | |||||||||||

| ✽4 Me asured values at 150°C x 22 h | |||||||||||

| *A SHORE A. | |||||||||||

| [Unit conversion] tensile strength: 10 kgf/cm2 = 0.98 Mpa; tear strength: 1 kgf/cm = 0.98 kN/m; volume resistivity: 1014Ω•cm = 1TΩ•cm | |||||||||||

| Classification | For general extrusion molding, FDA, BfR | For tubing | |||||||||||||

| Grade | KE-541-U*³ | KE-551-U*³ | KE-561-U*³ | KE-571-U*³ | KE-581-U*³ | KE-153-U | KE-174-U | KE-1551-U*³ | KE-1571-U*³ | ||||||

| Appearance | Milky white translucent | Miky white translucent | |||||||||||||

| Density 23℃ g/cm³ | 1.10 | 1.14 | 1.17 | 1.22 | 1.24 | 1.16 | 1.21 | 1.16 | 1.19 | ||||||

| Williams plasticity (10 min after remix) | 150 | 200 | 250 | 360 | 430 | 260 | 370 | 270 | 320 | ||||||

| Curing agent | Curing agent name | C-23N | C-25A/B | C-23N | C-25A/B | C-23N | C-25A/B | C-23N | C-25A/B | C-23N | C-25A/B | C-25A/B | C-25A/B | C-23N | C-23N |

| Standard addition quantity*¹ | 1.0 | 0.5/2.0 | 1.0 | 0.5/2.0 | 1.0 | 0.5/2.0 | 1.0 | 0.5/2.0 | 1.0 | 0.5/2.0 | 0.5/2.0 | 0.5/2.0 | 0.8 | 0.7 | |

| Linear shrinkage*² % | — | — | — | — | — | — | — | 3.3 | — | ||||||

| Physical strength | Hardness Durometer A | 40 | 40 | 50 | 50 | 63 | 62 | 70 | 68 | 79 | 77 | 53 | 71 | 56 | 74 |

| Tensile strength MPa | 8.0 | 8.2 | 10.5 | 9.8 | 11.5 | 11.5 | 11.0 | 11.0 | 10.5 | 10.5 | 10.0 | 8.1 | 10.5 | 9.5 | |

| Elongation at break % | 550 | 690 | 530 | 590 | 450 | 470 | 430 | 450 | 310 | 430 | 650 | 520 | 530 | 370 | |

| Tear strength crescent piece kN/m | 10 | 22 | 13 | 26 | 15 | 24 | 19 | 26 | 13 | 23 | 36 | 37 | 16 | 23 | |

| Compression set 180℃ x 22 h | 12*4 | 9*5 | 8*4 | 9*5 | 11*4 | 9*5 | 13*4 | 9*5 | 14*4 | 9*5 | — | — | — | 35*5 | |

| Dielectric breakdown strength Normal state kV | — | — | 26 | — | 25 | — | 26 | — | 29 | — | 26 | 28 | 28 | 25 | |

| Volume resistivity Normal state TΩ.m | 30 | — | 70 | — | 300 | — | 500 | — | 700 | — | 900 | 650 | 600 | 600 | |

| Classification | High strength | Low hardness, high elongation | Flame retardance | |||||||||

| Grade | KE-555-U* | KE-131-U | KE-5620W-U | |||||||||

| Appearance | Pale yellow | Milky white translucent | White | Black | Charcoal | Charcoal | Translucent | |||||

| Density 23℃ g/cm³ | 1.17 | 1.21 | 1.07 | 1.06 | 1.13 | 1.13 | 1.40 | 1.38 | 1.49 | 1.42 | 1.20 | |

| 310 | 320 | 150 | 150 | 170 | 180 | 240 | 230 | 230 | 300 | 330 | ||

| Curing agent | Curing agent name | C-8 | C-8 | C-8 | C-8 | C-8A | C-15 | X-93-1609*6/C-3 | C-3 | C-3 | C-25A/B | |

| Standard addition quantity*¹ | 2.0 | 2.0 | 2.0 | 2.0 | 0.5 | 1.5 | 0.1/1.3 | 1.3 | 1.3 | 1.0/2.0 | ||

| Linear shrinkage*² % | 4.0 | 4.0 | 4.7 | 4.5 | 3.8 | 4.1 | 3.1 | 3.2 | 2.7 | 2.7 | 3.4 | |

| Physical strength | Hardness Durometer A | 53 | 70 | 18 | 23 | 35 | 39 | 59 | 57 | 60 | 57 | 70 |

| Tensile strength MPa | 11.0 | 9.4 | 7.4 | 5.0 | 9.7 | 9.7 | 6.5 | 7.0 | 7.2 | 7.3 | 7.7 | |

| Elongation at break % | 650 | 550 | 1,060 | 770 | 880 | 700 | 410 | 430 | 290 | 320 | 370 | |

| Tear strength crescent piece kN/m | 35 | 41 | 18 | 10 | 34 | 17 | 12 | 11 | 13 | 10 | 14 | |

| Compression set 180℃ x 22 h | 31 | 18 | — | 22 | 20*5 | 9*5 | 21 | 27 | 16 | 22 | 20 | |

| Dielectric breakdown strength Normal state kV | 27 | 27 | — | — | — | — | 27 | 28 | 27 | 29 | 19 | |

| Volume resistivity Normal state TΩ.m | 100 | 200 | — | — | — | — | 50 | 80 | 240 | 8 | 300 | |

| Flame retardance UL94*7 | — | — | — | — | — | — | V-0 | V-0 | V-0 | V-0 | V-1 | |

| Measurement: in accordance with JIS K 6249 Test pieces: 165°C x 10 min (press cure), 200°C x 4 h (post cure) | ||||||||||||

| ✽1 Standard addition quantity is the quantity of the curing agent added to 100 parts compound | ||||||||||||

| ✽2 Linear shrinkage calues differ according to the curing agent used | ||||||||||||

| ✽3 Test pieces: 120°C x 10 min (press cure), 200°C 4 h (post cure) | ||||||||||||

| ✽4 Measured values at 100°C x 22 h | ||||||||||||

| ✽5 Measured values at 150°C x 22 h | ||||||||||||

| ✽6 X-93-1609 is a flame retardant | ||||||||||||

| ✽7 UL File No.E48923 | ||||||||||||

| ✽A SHORE A | ||||||||||||

| ⋆ Not available in U.S.. | ||||||||||||

| [Unit conversion] tensile strength: 10 kgf/cm2 = 0.98 Mpa; tear strength: 1 kgf/cm = 0.98 kN/m; volume resistivity: 1014Ω•cm = 1TΩ•cm | ||||||||||||

成型通用

描述

KCC通用挤出硅橡胶产品是肖氏A硬度的化合物30, 40, 50, 60,70 和 80。它们旨在促进与增量填料和添加剂的混合。除了机械和电气性能外,这些产品还具有出色的加工能力和透明度。此外,通过混合每个等级可以制成各种硬度等级。橡胶件是通常采用挤出工艺制成,也可以采用压缩成型方法。

特征

- 良好平衡的机械性能

- 在挤出和成型等方面具有出色的加工能力

- 良好的回弹性

- 通过 UL 94 HB 测试

- 符合 FDA 和 BfR 对食品接触物品的建议

应用

- 一般工业用品(密封件、型材、片材、垫圈)

- 食品接触用品(管道、管材、厨具、包装)

- 电气用品

- 产品等级

- 产品等级(续)

- 产品等级(续)

| Properties | Test method | Unit | SH0030U | SH0040U | SH0050U | SH0060U | SH0070U | SH0080U |

|---|---|---|---|---|---|---|---|---|

| Appearance | ASTM E1767 | — | Translucent | Light grey | ||||

| Williams plasticity | ASTM D926 | — | 130 | 160 | 180 | 210 | 240 | 290 |

| Specific gravity | ASTM D792 | — | 1.10 | 1.13 | 1.15 | 1.23 | 1.30 | 1.44 |

| Hardness | ASTM D2240 | Shore A | 30 | 40 | 50 | 60 | 70 | 80 |

| Tensile strength | ASTM D412 | Mpa | 7.5 | 8.5 | 9.0 | 8.0 | 7.9 | 7.0 |

| Elongation | ASTM D412 | % | 850 | 700 | 500 | 250 | 180 | 120 |

| Tear strength | ASTM D624 C | N/mm | 20 | 24 | 20 | 22 | 20 | 16 |

| Resilience | ASTM D1054 | % | 58 | 63 | 63 | 52 | 49 | 44 |

| Compression set 22hrs at 175℃ | ASTM D395 | % | 20 | 18 | 18 | 14 | 14 | 25 |

| ※ Curing agent : KC-8 (2,5-dimethyl 2,5-di(t-butyl peroxy) hexane 45% paste) 0.5 phr | ||||||||

| ※ Curing condition : 10mins at 170℃ press cure → 4 hours at 200 ℃ hot air. | ||||||||

| Properties | Test method | Unit | SH5060U | SH5070U | SH5180U | SH5360U | SH5960U |

|---|---|---|---|---|---|---|---|

| Appearance | ASTM E1767 | — | Translucent | ||||

| Williams plasticity | ASTM D926 | — | 210 | 250 | 300 | 220 | 210 |

| Specific gravity | ASTM D792 | — | 1.18 | 1.20 | 1.22 | 1.18 | 1.18 |

| Hardness | ASTM D2240 | Shore A | 60 | 70 | 80 | 60 | 60 |

| Tensile strength | ASTM D412 | Mpa | 8.5 | 7.7 | 7.0 | 8.5 | 8.5 |

| Elongation | ASTM D412 | % | 400 | 230 | 190 | 350 | 400 |

| Tear strength | ASTM D624 C | N/mm | 22 | 24 | 24 | 25 | 26 |

| Resilience | ASTM D1054 | % | 58 | 57 | 50 | 59 | 62 |

| Compression set 22hrs at 175℃ | ASTM D395 | % | 16 | 17 | 15 | 16 | 19 |

| Properties | Test method | Unit | SH830U | SH840U | SH850U | SH5860U |

|---|---|---|---|---|---|---|

| Appearance | ASTM E1767 | — | Translucent | |||

| Williams plasticity | ASTM D926 | — | 130 | 160 | 190 | 210 |

| Specific gravity | ASTM D792 | — | 1.10 | 1.13 | 1.16 | 1.17 |

| Hardness | ASTM D2240 | Shore A | 30 | 40 | 50 | 60 |

| Tensile strength | ASTM D412 | Mpa | 8.3 | 7.3 | 7.5 | 7.6 |

| Elongation | ASTM D412 | % | 680 | 550 | 360 | 210 |

| Tear strength | ASTM D624 C | N/mm | 18 | 20 | 22 | 19 |

| Resilience | ASTM D1054 | % | 56 | 61 | 62 | 70 |

| Compression set 22hrs at 175℃ | ASTM D395 | % | 25 | 19 | 18 | 12 |

| ※ Curing agent : KC-8 (2,5-dimethyl 2,5-di(t-butyl peroxy) hexane 45% paste) 0.5 phr | ||||||

| ※ Curing condition : 10mins at 170℃ press cure → 4 hours at 200 ℃ hot air. | ||||||

挤出通用

描述

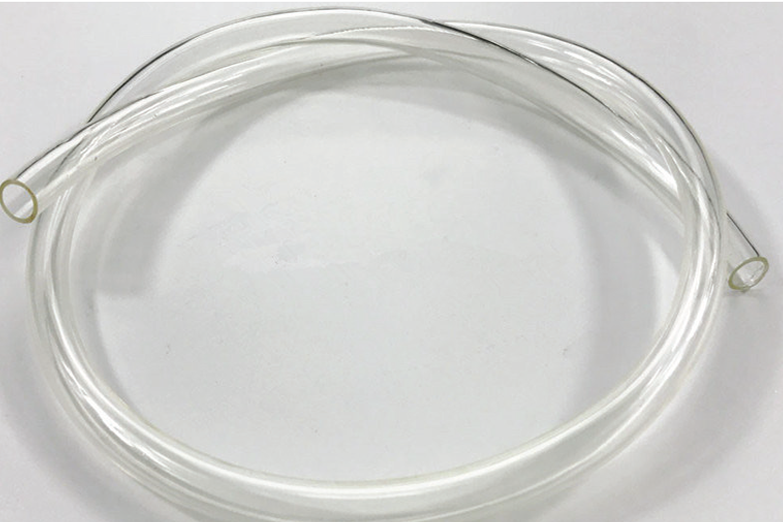

KCC通用挤出硅橡胶产品是肖氏A硬度的化合物30, 40, 50, 60,70 和 80。它们旨在促进与增量填料和添加剂的混合。除了机械和电气性能外,这些产品还具有出色的加工能力和透明度。此外,通过混合每个等级可以制成各种硬度等级。橡胶件是通常采用挤出工艺制成,也可以采用压缩成型方法。

特征

- 优异的机械和电气性能

- 在挤出和成型等方面具有出色的加工能力

- 良好的透明度

- 使用 SH0008B 添加剂稳定时具有良好的耐热性

- 符合 FDA 和 BfR 对食品接触物品的建议

应用

- 一般工业用品(密封件、型材、片材、垫圈)

- 食品接触用品(管道、管材、厨具、包装)

- 电气用品

- 产品等级

- 产品等级(续)

| Properties | Test method | Unit | SH1021U | SH1032U | SH1040U | SH1041U | SH1050U |

|---|---|---|---|---|---|---|---|

| Appearance | ASTM E1767 | — | Transparent | ||||

| Williams plasticity | ASTM D926 | — | 150 | 150 | 150 | 160 | 180 |

| Specific gravity | ASTM D792 | — | 1.09 | 1.10 | 1.11 | 1.12 | 1.13 |

| Hardness | ASTM D2240 | Shore A | 33 | 38 | 42 | 45 | 52 |

| Tensile strength | ASTM D412 | Mpa | 7.0 | 6.8 | 7.0 | 8.0 | 8.5 |

| Elongation | ASTM D412 | % | 610 | 550 | 500 | 550 | 450 |

| Tear strength | ASTM D624 C | N/mm | 15 | 20 | 20 | 23 | 24 |

| Resilience | ASTM D1054 | % | 13 | 10 | 10 | 14 | 13 |

| Compression set 22hrs at 175℃ | ASTM D395 | % | 85 | 55 | 60 | 60 | 43 |

| Volume resistivity | ASTM D257 | Ω.cm | 1.6X10(16) | 1.7X10(16) | 1.7X10(16) | 2.7X10(16) | 2.1X10(15) |

| Dielectric strength | ASTM D149 | kV/mm | 24 | 25 | 23 | 22 | 22 |

| ※ Curing agent : KC-8 (2,5-dimethyl 2,5-di(t-butyl peroxy) hexane 45% paste) 0.5 phr | |||||||

| ※ Curing condition : 10mins at 170℃ press cure → 4 hours at 200 ℃ hot air. | |||||||

| Properties | Test method | Unit | SH1060U | SH1061U | SH1070U | SH1072U | SH1073U | SH1080U |

|---|---|---|---|---|---|---|---|---|

| Appearance | ASTM E1767 | — | Transparent | |||||

| Williams plasticity | ASTM D926 | — | 220 | 210 | 275 | 270 | 270 | 300 |

| Specific gravity | ASTM D792 | — | 1.16 | 1.16 | 1.19 | 1.18 | 1.19 | 1.2 |

| Hardness | ASTM D2240 | Shore A | 62 | 62 | 72 | 72 | 72 | 82 |

| Tensile strength | ASTM D412 | Mpa | 9.5 | 9.5 | 9.5 | 10.0 | 9.5 | 9.0 |

| Elongation | ASTM D412 | % | 350 | 250 | 300 | 300 | 420 | 160 |

| Tear strength | ASTM D624 C | N/mm | 25 | 27 | 25 | 29 | 28 | 25 |

| Resilience | ASTM D1054 | % | 15 | 15 | 18 | 15 | 25 | 10 |

| Compression set 22hrs at 175℃ | ASTM D395 | % | 35 | 35 | 45 | 33 | 60 | 30 |

| Volume resistivity | ASTM D257 | Ω.cm | 1.6X10(15) | 44X10(16) | 3.8X10(15) | 4.0X10(16) | 1.0X10(15) | 7.1X10(14) |

| Dielectric strength | ASTM D149 | kV/mm | 27 | 28 | 26 | 27 | 28 | 22 |

| ※ Curing agent : KC-8 (2,5-dimethyl 2,5-di(t-butyl peroxy) hexane 45% paste) 0.5 phr | ||||||||

| ※ Curing condition : 10mins at 170℃ press cure → 4 hours at 200 ℃ hot air. | ||||||||

低硬度 HTV

描述

这些产品在固化状态下具有低硬度(肖氏 A 硬度 9 ~ 20)。可用于需要柔软手感的运动用品、医疗用品等硅橡胶制品

特征

- 低邵氏 A 硬度和高弹性伸长率

- 出色的成型和注塑加工能力

- 符合 FDA 和 BfR 对食品接触制品的建议

应用

- 游泳用品(泳帽、护目镜带)

- 婴儿护理用品(玩具、盖子)

- 高弹性制品(条带、胶带)

| Properties | Test method | Unit | SH0005U | SH1020U | SH0010U | SH0020U |

|---|---|---|---|---|---|---|

| Appearance | ASTM E1767 | — | Transparent | Translucent | ||

| Williams plasticity | ASTM D926 | — | 125 | 105 | 90 | 100 |

| Specific gravity | ASTM D792 | — | 1.03 | 1.08 | 1.06 | 1.08 |

| Hardness | ASTM D2240 | Shore A | 9 | 23 | 10 | 22 |

| Tensile strength | ASTM D412 | Mpa | 2.3 | 4.0 | 4.0 | 5.5 |

| Elongation | ASTM D412 | % | 950 | 970 | 950 | 1,000 |

| Tear strength | ASTM D624 C | N/mm | 7 | 15 | 9 | 13 |

| Compression set 22hrs at 175℃ | ASTM D395 | % | 55 | 65 | 26 | 18 |

| ※ Curing agent : KC-8 (2,5-dimethyl 2,5-di(t-butyl peroxy) hexane 45% paste) 0.5 phr | ||||||

| ※ Curing condition : 10mins at 170℃ press cure → 4 hours at 200 ℃ hot air. | ||||||

高硬度 HTV

描述

该系列由固化状态下硬度为 90(鞋 A)的高硬度硅橡胶化合物组成。这些较硬的牌号可以用来调整其他牌号的硬度,它们也有自己的应用

特征

- 超高邵氏 A 硬度 90

- 高威廉斯可塑性和高生坯强度

- 符合 FDA 和 BfR 对食品接触物品的建议

应用

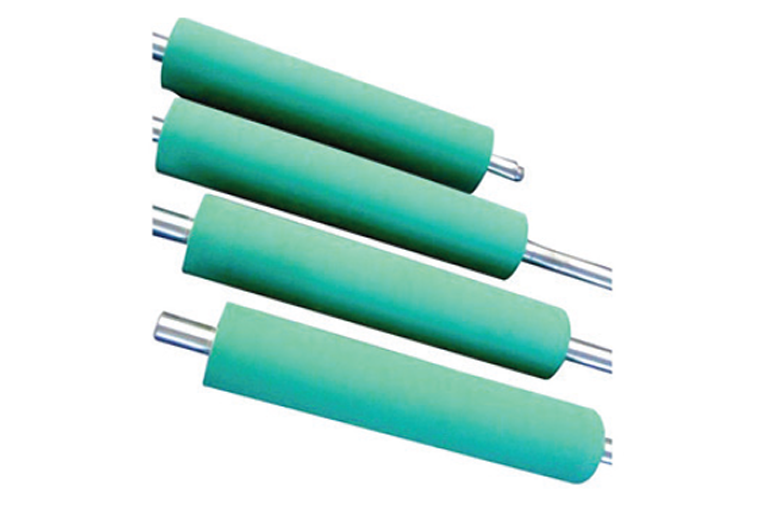

- 一般工业用品(键盘的键顶、特殊滚轮)

- Fiid 接触用品(厨具、瓶子

| Properties | Test method | Unit | SH5190U | SH1090U |

|---|---|---|---|---|

| Appearance | ASTM E1767 | — | Translucent | Transparent |

| Williams plasticity | ASTM D926 | — | 300 | 340 |

| Specific gravity | ASTM D792 | — | 1.25 | 1.23 |

| Hardness | ASTM D2240 | Shore A | 90 | 90 |

| Tensile strength | ASTM D412 | Mpa | 8.5 | 9.5 |

| Elongation | ASTM D412 | % | 50 | 150 |

| Tear strength | ASTM D624 C | N/mm | 16 | 24 |

| Compression set 22hrs at 175℃ | ASTM D395 | % | 20 | 19 |

| ※ Curing agent : KC-8 (2,5-dimethyl 2,5-di(t-butyl peroxy) hexane 45% paste) 0.5 phr | ||||

| ※ Curing condition : 10mins at 170℃ press cure → 4 hours at 200 ℃ hot air. | ||||

高撕裂强度 HTV

描述

这些产品具有优异的机械性能,包括高撕裂强度,它们用于形状复杂的零件、大型成型零件等应用。SH7340U和SH7255U本身俱有良好的热稳定性,SH7060U和SH7070U

与添加剂SH0008B具有良好的热稳定性。

特征

- 高撕裂强度和高拉伸强度

- 在成型和挤出等方面具有出色的加工能力

- 良好的耐热性(SH7340U 和 SH7255U)

- 符合 FDA 和 BfR 对食品接触物品的建议(SH7060U 和 SH7070U)

应用

- 一般工业零件(橡胶卷标纺织品、旋铸、片材、垫圈)

- 高机械橡胶制品

- 汽车制品(消声器衣架)

| Properties | Test method | Unit | SH7340U | SH7255U | SH7060U | SH7070U |

|---|---|---|---|---|---|---|

| Appearance | ASTM E1767 | — | Transparent | |||

| Williams plasticity | ASTM D926 | — | 150 | 215 | 200 | 240 |

| Specific gravity | ASTM D792 | — | 1.12 | 1.16 | 1.16 | 1.18 |

| Hardness | ASTM D2240 | Shore A | 40 | 60 | 60 | 70 |

| Tensile strength | ASTM D412 | Mpa | 8.3 | 10.3 | 9.5 | 9.0 |

| Elongation | ASTM D412 | % | 980 | 850 | 800 | 700 |

| Tear strength | ASTM D624 C | N/mm | 45 | 45 | 40 | 42 |

| Resilience | ASTM D1054 | % | 37 | 39 | 36 | 39 |

| Compression set 22hrs at 175℃ | ASTM D395 | % | 24 | 29 | 26 | 28 |

| Property change after heat aging 72 hours at 220℃ | ||||||

| Hardness | ASTM D573 | — | -2 | 2 | 6 | 5 |

| Tensile strength | % | -28 | -19 | -33 | -28 | |

| Elongation | % | -25 | -23 | -38 | -36 | |

| ※ Curing agent : KC-8 (2,5-dimethyl 2,5-di(t-butyl peroxy) hexane 45% paste) 0.5 phr | ||||||

| ※ Curing condition : 10mins at 170℃ press cure → 4 hours at 200 ℃ hot air. | ||||||

低压缩永久变形 HTV

描述

这些产品旨在具有出色的压缩永久变形,无需后固化。

特征

- 低压缩永久变形,无需后固化。

应用

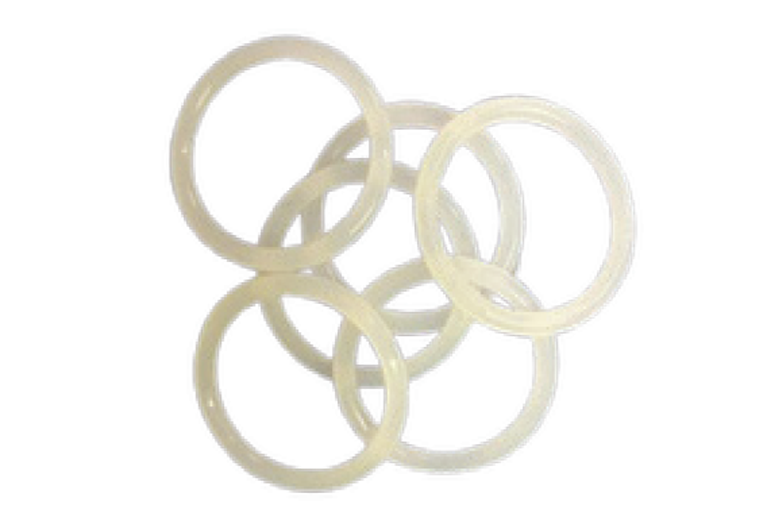

- 一般工业用品

(OA 辊、填料、垫圈、片材、密封件、O 形圈)

| Properties | Test method | Unit | SH2533U | SH2540U | SH2580U |

|---|---|---|---|---|---|

| Appearance | ASTM E1767 | — | Translucent | Light yellow | Beige |

| Williams plasticity | ASTM D926 | — | 110 | 140 | 250 |

| Specific gravity | ASTM D792 | — | 1.04 | 1.10 | 1.43 |

| Hardness | ASTM D2240 | Shore A | 33 | 40 | 80 |

| Tensile strength | ASTM D412 | Mpa | 1.8 | 7.0 | 7.5 |

| Elongation | ASTM D412 | % | 260 | 550 | 100 |

| Tear strength | ASTM D624 C | N/mm | 9 | 23 | 18 |

| Resilience | ASTM D1054 | % | 85 | 67 | 53 |

| Compression set 22hrs at 175℃ | ASTM D395 | % | 7 | 13 | 10 |

| Property change after heat aging 72 hours at 220℃ | |||||

| Hardness | ASTM D573 | — | -10 | -5 | 5 |

| Tensile strength | % | -32 | -20 | -30 | |

| Elongation | % | 5 | 5 | -50 | |

| ※ Curing agent : KC-8 (2,5-dimethyl 2,5-di(t-butyl peroxy) hexane 45% paste) 1.0 phr | |||||

| ※ Curing condition : | |||||

| - SH2533U : 10mins at 170℃ press cure → 4 hours at 200 ℃ hot air. | |||||

| - SH2540U, SH2580U : 10mins t 170℃ press cure | |||||

耐蒸汽 HTV

描述

这些产品用于需要耐蒸汽、耐热和耐油以及在高温下具有优异机械性能的各种零件。

肖氏 A 硬度范围为 50 至 70。

特征

- 耐蒸汽和耐热性能

- 低压缩永久变形

- 出色的加工能力

应用

- 包装(蒸汽电饭锅、蒸汽熨斗、罐子、高压釜等)

- 其他工业用品(O 形圈、垫圈、阀门)

| Properties | Test method | Unit | SH6050U | SH6060U | SH6070U |

|---|---|---|---|---|---|

| Appearance | ASTM E1767 | — | Light yellow | ||

| Williams plasticity | ASTM D926 | — | 170 | 220 | 210 |

| Specific gravity | ASTM D792 | — | 1.13 | 1.15 | 1.17 |

| Hardness | ASTM D2240 | Shore A | 50 | 60 | 70 |

| Tensile strength | ASTM D412 | Mpa | 8 | 9.0 | 7.0 |

| Elongation | ASTM D412 | % | 500 | 530 | 120 |

| Tear strength | ASTM D624 C | N/mm | 23 | 27 | 20 |

| Compression set 22hrs at 175℃ | ASTM D395 | % | 10 | 13 | 6 |

| Property change after heat aging 72 hours at 220℃ | |||||

| Hardness | ASTM D573 | — | 1 | 1 | -1 |

| Tensile strength | % | -7 | -24 | -33 | |

| Elongation | % | -29 | -35 | -23 | |

| Property change after heat aging 168 hours at 3 bars, 130℃ | |||||

| Hardness | ASTM D471 | — | 2 | 4 | -1 |

| Tensile strength | % | -2 | -2 | -8 | |

| Elongation | % | -13 | -14 | -1 | |

| Volume | % | -1 | -1 | -1 | |

| ※ Curing agent : KC-8 (2,5-dimethyl 2,5-di(t-butyl peroxy) hexane 45% paste) 0.5 phr | |||||

| ※ Curing condition : 10mins at 170℃ press cure → 4 hours at 200 ℃ hot air. | |||||

导电 HTV

描述

导电系列是热固化化合物,用于压制成型、挤出和日历。肖氏 A 硬度范围为 60 至 80。

特徵

- 耐蒸汽和耐热性能

- 低压缩永久变形

- 出色的加工能力

应用

- 包装(蒸汽电饭锅、蒸汽熨斗、罐子、高压釜等)

- 其他工业用品(O 形圈、垫圈、阀门)

| Properties | Test method | Unit | SH6540U | SH6560U | SH6570U | SH6580U |

|---|---|---|---|---|---|---|

| Appearance | ASTM E1767 | — | Black | |||

| Williams plasticity | ASTM D926 | — | 200 | 580 | 730 | 800 |

| Specific gravity | ASTM D792 | — | 1.08 | 1.17 | 1.19 | 1.21 |

| Hardness | ASTM D2240 | Shore A | 36 | 60 | 70 | 80 |

| Tensile strength | ASTM D412 | Mpa | 4.5 | 6.7 | 6.5 | 7.0 |

| Elongation | ASTM D412 | % | 700 | 380 | 180 | 90 |

| Tear strength | ASTM D624 C | N/mm | 15 | 21 | 15 | 14 |

| Volume resistivity | ASTM D991 | Ω.cm | 45 | 9.0 | 5.0 | 3.0 |

| ※ Curing agent : KC-8 (2,5-dimethyl 2,5-di(t-butyl peroxy) hexane 45% paste) 2.0 phr | ||||||

| ※ Curing condition : 10mins at 170℃ press cure → 4 hours at 200 ℃ hot air. | ||||||

导热 HTV

描述

固化产品具有阻燃性 (UL 94 V-0) 和导热性 (~ 1.0 W/mK)。因此,它被用于电子设备以从设备中去除热量。

特征

- 高导热性

- 高耐热性和阻燃性

- 优异的成型和挤出等加工能力

应用

- 用于电子设备的导热制品(散热垫、片、盖)

| Properties | Test method | Unit | SH6280U |

|---|---|---|---|

| Appearance | ASTM E1767 | — | Dark grey |

| Williams plasticity | ASTM D926 | — | 290 |

| Specific gravity | ASTM D792 | — | 2.17 |

| Hardness | ASTM D2240 | Shore A | 80 |

| Tensile strength | ASTM D412 | Mpa | 4.0 |

| Elongation | ASTM D412 | % | 85 |

| Tear strength | ASTM D624 C | N/mm | 9 |

| Volume resistivity | ASTM D257 | Ω.cm | 3.0X10(14) |

| Dielectric strength | ASTM D149 | KV/mm | 26 |

| Thermal conductivity | ASTM D5470 | W/m.k | 1.0 |

| Property change after heat aging 72 hours at 250℃ | |||

| Hardness | ASTM D573 | — | 1 |

| Tensile strength | % | -10 | |

| Elongation | % | -13 | |

| ※ Curing agent : KC-8 (2,5-dimethyl 2,5-di(t-butyl peroxy) hexane 45% paste) 2.0 phr | |||

| ※ Curing condition : 10mins at 170℃ press cure → 4 hours at 200 ℃ hot air. | |||

阻燃 HTV

描述

这些产品分别是阻燃等级 (UL 94 V-0)。(UL 文件编号:QMFZ8.E253047)

特征

- 阻燃等级(UL 94 V-0)

- 在成型和挤出等方面具有出色的加工能力

- 良好的机械和电气性能

应用

- 电子产品(高压帽、背光灯座、特殊宽幅)

- 建筑用品(防火垫圈)

| Properties | Test method | Unit | SH1520U | SH1550U | SH1572U |

|---|---|---|---|---|---|

| Appearance | ASTM E1767 | — | Dark grey | White | |

| Williams plasticity | ASTM D926 | — | 200 | 200 | 220 |

| Specific gravity | ASTM D792 | — | 1.44 | 1.42 | 1.48 |

| Hardness | ASTM D2240 | Shore A | 60 | 55 | 70 |

| Tensile strength | ASTM D412 | Mpa | 7.8 | 8.7 | 6.3 |

| Elongation | ASTM D412 | % | 320 | 450 | 160 |

| Tear strength | ASTM D624 C | N/mm | 23 | 23 | 16 |

| Volume resistivity | ASTM D257 | Ω.cm | 9.0X10(15) | 3.0X10(16) | 3.4X10(15) |

| Dielectric strength | ASTM D149 | KV/mm | 24 | 26 | 24 |

| Flame retardancy | UL 94 | — | V-0 | V-0 | V-0 |

| ※ Curing agent : KC-8 (2,5-dimethyl 2,5-di(t-butyl peroxy) hexane 45% paste) 2.0 phr | |||||

| ※ Curing condition : 10mins at 170℃ press cure → 4 hours at 200 ℃ hot air. | |||||

电线电缆 HTV

描述

这些产品是电线电缆挤出级,肖氏硬度为 60 和 70。它们具有优异的挤出性能。

特征

- 优异的温度稳定性

- 优异的挤出加工能力

- 良好的机械和电气性能

应用

- 电线和电缆(通用/热稳定/高介电设备)

- 玻璃和陶瓷包装

| Properties | Test method | Unit | SH1160U | SH1170U | SH1270U | SH1775U | SH1370U |

|---|---|---|---|---|---|---|---|

| Appearance | ASTM E1767 | — | White | Belge | White | Light grey | Light yellow |

| Williams plasticity | ASTM D926 | — | 200 | 200 | 230 | 210 | 240 |

| Specific gravity | ASTM D792 | — | 1.40 | 1.40 | 1.33 | 1.29 | 1.20 |

| Hardness | ASTM D2240 | Shore A | 60 | 70 | 70 | 65 | 70 |

| Tensile strength | ASTM D412 | Mpa | 7.5 | 7.5 | 8.0 | 7.5 | 9.0 |

| Elongation | ASTM D412 | % | 330 | 200 | 250 | 200 | 260 |

| Tear strength | ASTM D624 C | N/mm | 23 | 18 | 24 | 17 | 23 |

| Volume resistivity | ASTM D257 | Ω.cm | 2.0X10(15) | 1.0X10(15) | 1.3X10(16) | 8.5X10(14) | 1.5X10(16) |

| Dielectric strength | ASTM D149 | KV/mm | 27 | 28 | 30 | 24 | 30 |

| Property change after heat aging as below condition | |||||||

| Hardness change | ASTM D573 | — | 1 | 1 | 7 | -3 | 2 |

| Tensile strength | ASTM D573 | — | 1 | 1 | 7 | -3 | 2 |

| Elongation change | % | -13 | -15 | -30 | -31 | -30 | |

| Elongation | % | -7 | -6 | -45 | -38 | -40 | |

| ※ Curing agent : KC-8 (2,5-dimethyl 2,5-di(t-butyl peroxy) hexane 45% paste) 2.0 phr | |||||||

| ※ Curing condition : 10mins at 170℃ press cure → 4 hours at 200 ℃ hot air. | |||||||

高压绝缘子用 HTV

描述

该产品是一种用于高胶粘剂绝缘应用的模塑料。它已经与过氧化物催化剂混合使用。

特征

- 出色的耐电痕性和耐腐蚀性

- 出色的耐候性和抗紫外线性

- 出色的电绝缘性能

- 出色的防水性

- 出色的注塑成型加工能力

应用

- 高压绝缘子、电缆终端和连接器

- 避雷器、悬式绝缘子

| Properties | Test method | Unit | SH4001Z | SH4001ZNC133 |

|---|---|---|---|---|

| Appearance | ASTM E1767 | — | Dark grey | Grey |

| Williams plasticity | ASTM D926 | — | 200 | 200 |

| Specific gravity | ASTM D792 | — | 1.55 | 1.55 |

| Hardness | ASTM D2240 | Shore A | 65 | 65 |

| Tensile strength | ASTM D412 | Mpa | 3.8 | 3.8 |

| Elongation | ASTM D412 | % | 220 | 280 |

| Tear strength | ASTM D624 C | N/mm | 16 | 15 |

| Volume resistivity | ASTM D257 | Ω.cm | 2.3X10(13) | 2.2X10(13) |

| Dielectric strength | ASTM D149 | KV/mm | 26 | 26 |

| Dielectric constant at 1 MHz | ASTM D150 | — | 3.8 | 3.8 |

| Dissipation factor at 1MHz | ASTM D150 | — | 0.01 | 0.01 |

| Tracking resistance | IEC 60587 | kV | 4.5 | 4.5 |

| ※ They are already mixed curing agent | ||||

| : KC-8 (2,5-dimethyl 2,5-di(t-butyl peroxy) hexane 45% paste) 1.0 phr | ||||

| ※ Curing condition : 10mins at 170℃ press cure | ||||

放油 HTV

描述

这些产品在固化后向表面弹性体制品释放润滑油。这允许容易的组装和防水性能。它们可以通过各种加工方法使用,例如注塑、传递模塑和压延。

特征

- 良好的耐热性和耐油性

- 优异的注塑、传递成型加工能力

- 良好的机械性能

应用

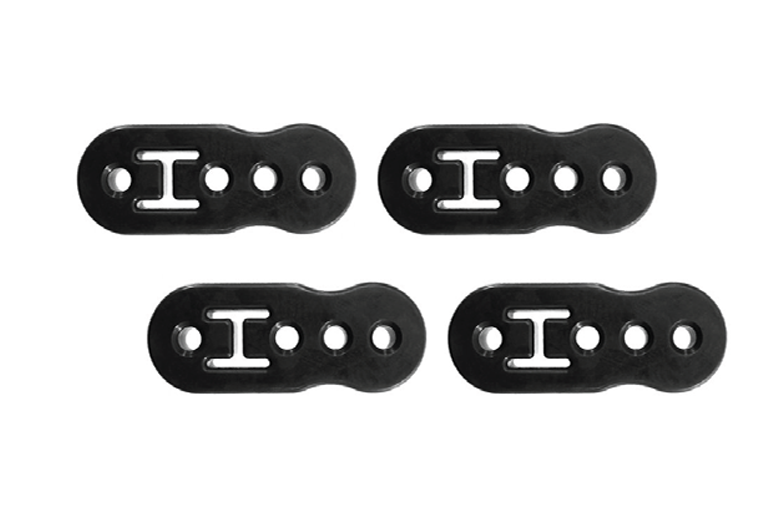

- 汽车用品(线束连接器、索环、单线垫圈、平垫圈)

- 工业用品(O 形圈、油封)

| Properties | Test method | Unit | SH9030U | SH9035U | SH9040U | SH9050U | SH9060U |

|---|---|---|---|---|---|---|---|

| Appearance | ASTM E1767 | — | Milky White | Beige | |||

| Williams plasticity | ASTM D926 | — | 150 | 175 | 175 | 170 | 210 |

| Specific gravity | ASTM D792 | — | 1.13 | 1.15 | 1.15 | 1.16 | 1.22 |

| Hardness | ASTM D2240 | Shore A | 30 | 32 | 40 | 50 | 60 |

| Tensile strength | ASTM D412 | Mpa | 8.5 | 9.5 | 8.5 | 8.5 | 8.0 |

| Elongation | ASTM D412 | % | 510 | 630 | 440 | 400 | 330 |

| Tear strength | ASTM D624 C | N/mm | 19 | 21 | 22 | 23 | 22 |

| Compression set 22hrs at 175℃ | ASTM D395 | W/m.k | 24 | 25 | 26 | 13 | 10.0 |

| Property change after heat aging 72 hours at 220℃ | |||||||

| Hardness | ASTM D573 | — | -2 | -3 | -1 | 2 | 5 |

| Tensile strength | % | -5 | -20 | -14 | -7 | -12 | |

| Elongation | % | -7 | -20 | -13 | -15 | -24 | |

| Property change after IRM 903 oil aging 72 hours at 150℃ | |||||||

| Hardness | ASTM D471 | — | -19 | -14 | -20 | -16 | -24 |

| Tensile strength | % | -47 | -38 | -40 | -37 | -24 | |

| Elongation | % | -20 | -16 | -15 | -30 | -13 | |

| Volume | % | 50 | 38 | 45 | 36 | 35 | |

| ※ Curing agent : KC-8 (2,5-dimethyl 2,5-di(t-butyl peroxy) hexane 45% paste) 0.5 phr | |||||||

| ※ Curing condition : 10mins at 170℃ press cure → 4 hours at 200 ℃ hot air. | |||||||

高抗疲劳 HTV

描述

这些产品专为高动态物品(键盘、单键球机)而设计

特徵

- 优异的动态耐久性

- 高回弹弹性

- 卓越的成型加工能力

- 高分散性

- 压缩永久变形

应用

- 电子产品(动态小键盘、键盘按键开关)

- 各种工业用途,具有高耐用性

| Properties | Test method | Unit | SH9141U | SH9151U | SH9161U | SH918U | SH9182U |

|---|---|---|---|---|---|---|---|

| Appearance | ASTM E1767 | — | Transparent | ||||

| Williams plasticity | ASTM D926 | — | 150 | 180 | 160 | 300 | 270 |

| Specific gravity | ASTM D792 | — | 1.08 | 1.11 | 1.11 | 1.19 | 1.18 |

| Hardness | ASTM D2240 | Shore A | 40 | 50 | 60 | 80 | 83 |

| Tensile strength | ASTM D412 | Mpa | 7.0 | 8.5 | 8.0 | 9.5 | 9.5 |

| Elongation | ASTM D412 | % | 470 | 420 | 250 | 200 | 200 |

| Tear strength | ASTM D624 C | N/mm | 25 | 30 | 25 | 20 | 23 |

| Resilience | ASTM D1054 | % | 80 | 78 | 75 | 60 | 63 |

| Compression set 22hrs at 175℃ | ASTM D395 | % | 12 | 11 | 12 | 13 | 13 |

| Fatigue resistant degree | ASTM D4482 | cycle | 6,000,000 | 1,500,000 | 1,650,000 | 500,000 | 1,000,000 |

| For SH9141U, SH9151U and SH9161U | |||||||

| ※ Curing agent : KC-8 (2,5-dimethyl 2,5-di(t-butyl peroxy) hexane 45% paste) 0.5 phr | |||||||

| ※ Curing condition : 10mins at 170℃ press cure → 4 hours at 200 ℃ hot air. | |||||||

| ※ Fatigue resistant test condition : 150% elongation 5 cycle/sec | |||||||

| For SH9181U and SH9182U | |||||||

| ※ Curing agent : KC-8 (2,5-dimethyl 2,5-di(t-butyl peroxy) hexane 45% paste) 0.5 phr | |||||||

| ※ Curing condition : 10mins at 170℃ press cure → 4 hours at 200 ℃ hot air. | |||||||

| ※ Fatigue resistant test condition : 150% elongation 5 cycle/sec | |||||||