橡胶化工

Pilflex 13 (防老剂)

- 产品特性

- 产品特性(续)

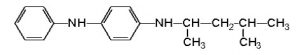

| Chemical Name | N-(1,3-dimethylbutyl)-N’-phenyl-p-phenylenediamine. (6PPD) | |

|---|---|---|

| Chemical Structure |

|

|

| CAS Reg. No. | 793-24-8 | |

| Mol. Wt. | 268 | |

| Product Specification | ||

| Parameter | Limits | Test Method |

| Product form | Pastilles | - |

| Color | Dark purple | - |

| Assay (Titration), % (min) | 97 | D 4937 |

| Melting Point (Initial), °C (min) | 46 | D 1519 |

| Melting Point (Final), °C | 48-51 | D 1519 |

| Heat Loss, % (max) | 0.3 | D 4571 |

| Ash, % (max) | 0.1 | D 4574 |

| Typical Data | ||

| Viscosity @ 60 °C, cps | 27-38 | NOCIL G-5 |

| Specific gravity at 60°C. | 0.986-1.00 | NOCIL G-25 |

| Bulk density , kg/m3 | 550 - 590 | NOCIL G-44 |

| Product Information | ||

| Solubility | Soluble in acetone and ethyl alcohol; moderately soluble in hydrocarbon solvents. Insoluble in water. | |

| Classification | High activity Antidegradant. | |

| Discoloration & Staining | Discolors white / colored products. Contact / Migration staining is experienced on other surfaces in contact with rubber products containing 6PPD. | |

| FDA Approval Status | Regulated for use in articles in contact with food under BgVV XXI, Category 3-4. Not regulated for use in articles in contact with food under FDA. | |

| Toxicity Data (Please refer to the latest Toxicological information.) | Slightly harmful by mouth. (Oral LD50rat 2500-3340 mg/kg). Not a skin or eye irritant. Unlikely to cause skin sensitization in man except individuals sensitized by other para phenylenediamines. | |

| Handling & Personal Protection | Ensure good ventilation and avoid creating dusty atmosphere. In case of eye or skin contacts wash out with clean water for 5 to 10 minutes. | |

| Storage | Always store in a cool (below 30ºC) & dry place in single stack pallets away from direct sun light or any other heat source to avoid compaction. | |

| Packaging | ||

| Paper Bag / Drum | Paper Bag: 20 kg / Fiber board drum: 50 kg. | |

| FIBC | 500 kg / 800 kg | |

| Storage Life | 12 months when stored as stated above. | |

| Color code | Green colored strip. | |

| TYPICAL DOSAGES OF PILFLex 13 | |||

|---|---|---|---|

| Product | Antioxidant / Antiozonant / Wax , phr | ||

| Rubber | Pilflex 13 | Pilnox TDQ | |

| Truck Tyres | NR-BR | 2.5-3.5 | 1 |

| Treads (Cross ply, Front Tyres) | NR | 3.0-3.5 | 1 |

| Treads (Cross ply, Rear Tyres) | NR-BR | 3.0-3.5 | 1 |

| Treads (Radials) | NR-BR | 2.7-3.0 | 1 |

| Sidewall (Cross ply) | NR-BR | 3.0-4.0 | 1 |

| Sidewall (Radials) | NR | 0.7-1.0 | 1 |

| Carcass (Cross ply) | NR | 0.7-1.0 | 1 |

| Carcass (Radial) | |||

| Passenger Tyres (Radials) | NR-SBR-BR | 2.5-3.0 | 1 |

| Tread | SBR-BR | 2.5-3.0 | 1 |

| Sidewall | NR-BR | 3.0-3.5 | 1 |

| Carcass | NR/ NR-SBR | 0.5 | 1 |

| Motor cycle / Scooter Tyres | SBR-BR | 1.75-2.0 | 1 |

| Tread | NR-SBR | 0.5 | 1 |

| Carcass | |||

| Auto Tubes | IIR | 0.5 | - |

| NR | 1 | 1 | |

| Flaps | NR/ NR-RR | 0.5 | 1 |

| Bicycle Tyre Treads | NR-RR | 0.5 | 1 |

| NR-BR-RR | 0.5 | 1 | |

| Bicycle Tubes | NR | 0.5 | 1 |

| Cycle Tyre curing bags | NR | 1 | 1.5-2.0 |

| Retreads | NR/NR-BR | 0.5-0.75 | 1 |

| Hot cure | NR-BR | 1 | 1 |

| Cold cure | SBR-BR | 1 | 1 |

| Cushion gum | NR | - | 1 |

| Conveyor belt cover | NR | 1.0-1.5 | 1.0-1.5 |

| NR-SBR | 1.0-1.5 | 1.0-1.5 | |

| V belts | NR | 1 | 1 |

| Base | NR | 0.5 | 1 |

| Cushion | |||

| Molded & Extruded goods | NR/NR-SBR | 0.5-1.0 | 1 |

| NBR | 0.5-1.0 | 1 | |

| * Paraffin wax may be used | |||

Pilflex MBT (促进剂)

- 產品特性

- 產品特性(續)

- 產品特性(續)

| Chemical Name | 2-mercaptobenzothiazole (MBT) | |

|---|---|---|

| Chemical Structure |

|

|

| CAS Reg. No. | 149-30-4 | |

| Mol. Wt. | 167 | |

| Product Specification | ||

| Parameter | Limits | Test Method |

| Product form | Powder (OT) | - |

| Color | Cream | - |

| Assay (Titration), % (min) | 96 | D 1991 |

| Melting Point (Initial), °C (min) | 170 | D 1519 |

| Melting Point (Final), °C | 176-183 | D 1519 |

| Heat Loss, % (max) | 0.4 | D 4571 |

| Ash, % (max) | 0.4 | D 4574 |

| Paraffinic Oil (<0.2% PCAH), % | 1.0-2.0 | NOCIL G-40 |

| Residue on 150 µm sieve, % (max) | 0.05 | D 5461 |

| Residue on 63 µm sieve, % (max) | 0.5 | D 5461 |

| Typical Data | ||

| Specific gravity at 25°C | 1.51 | D 1817 |

| Bulk density, kg/m3 | 400 - 440 | NOCIL G-44 |

| Bulk density (Comp), kg/m3 | 580 - 620 | NOCIL G-44 |

| Product Information | ||

| Solubility | Soluble in acetone, chloroform and dilute alkali. Slightly soluble in alcohol. Insoluble in water and gasoline. | |

| Classification | Semi ultra fast accelerator. | |

| Discoloration & Staining | Non-discoloring and Non-staining. | |

| FDA Approval Status | Regulated for use in articles in contact with food under FDA 21 CFR 177.2600, 175.105, 176.300 and BgVV XXI categories 1-4 & ‘Sonderkategorie’. | |

| Toxicity Data (Please refer to the latest Toxicological information.) | Practically non-harmful. (Oral LD50rat over 5000 mg/kg). Not a skin or eye irritant. | |

| Handling & Personal Protection | Ensure good ventilation and avoid creating dusty atmosphere. In case of eye or skin contacts wash out with clean water for 5 to 10 minutes. | |

| Storage | Store at room temperature in a cool, dry and well ventilated place. Avoid exposure of the packaged material / product to direct sunlight & heat. | |

| Packaging | ||

| Paper-Fabric Bag | 20 kg | |

| FIBC | 500 kg | |

| Storage Life | 24 months | |

| Color code | Blue colored strip. | |

| TYPICAL DOSAGES OF PILCURE MBT | |||||||

|---|---|---|---|---|---|---|---|

| Product | Rubber | Accelerator / Sulphur, phr | |||||

| MBT | MBTS | MOR | TMTD | ZDEC | S | ||

| Motor Cycle, Scooter | NR- | 0.8-1.0** | - | - | 0.07-0.15 | - | 2.2-2.75* |

| Tyre Treads | SBR / BR | ||||||

| Auto Tubes | IIR | 0.5 | - | - | 1 | 0.0-0.2 | 1.5 |

| Cycle Tyre Treads | NR-RR | 0.6** | 0.3 | - | 0.1-0.15 | - | 2.2-2.5 |

| NR-SBR / BR | 0.8** | 0.4 | - | 0.1-0.2 | - | 2.2 | |

| Conveyor Belt Cover | NR | 0.70** | 0.25 | - | 0.0-0.15 | - | 2.75* |

| SBR | 1.0** | 0.4 | - | 0.0-0.20 | - | 2.2 | |

| Transmission Belts | NR | 0.3 | - | 0.8 | - | - | 3.0 |

| General Purpose | NR | 0.5 | - | - | 2.0-2.5 | - | 0.3 |

| Heat Resistant | |||||||

| V Belts | NR | 0.2 | - | 0.6** | - | - | 3.0 |

| Base | NR | 0.4 | - | 0.6** | - | - | 2.4 |

| Cushion | |||||||

| Retreading Materials | NR | 0.2 | - | 0.7** | - | - | 2.4* |

| Cushion-Hot Cure | NR | 1 | - | - | TMTM-0.2 | - | 2.4* |

| Cushion-Cold Cure | NR | 0.6 | 0.4 | - | - | - | 4.0* |

| Vulcanizing Solution | |||||||

| Footwear | NR-SBR | 0.8 | - | - | 0.2-0.3 | - | 2.0 |

| DV Soles | NR-SBR | 1 | 0.1-0.2 | 2.3 | |||

| Microcellular Soles | NR-SBR | 1 | 0.1-0.2 | 2.5 | |||

| Neolite Soles | |||||||

| Hot Air Cured Products | NR | 0.8 | - | - | - | 0.3-0.4 | 2.5 |

| Rubberized Fabric and Rubber Sheeting | |||||||

| Cables | NR | 1 | - | - | TMTM | - | 1.2 |

| SBR | 1.5 | 0.2-0.3 | 1 | ||||

| Misc. Molded and Extruded Products | NR | 0.8-1.0 | - | - | 0.0-0.2 | - | 2.4 |

| SBR | 1.2-1.5 | 2.2 | |||||

| NBR | 1.2-1.5 | 1.5 | |||||

| Note: | |||||||

| * Insoluble Sulphur (100% active content basis) | |||||||

| ** Pre Vulcanization Inhibitor may be incorporated at 0.2-0.5 phr levels for desired | |||||||

| scorch safety, ensuring compliance with vulcanizate properties. | |||||||

| PILCURE MBT based Cure Systems for sulphur cured EPDM Products | |||||

| Accelerator & Sulphur | Cure Systems (phr) | ||||

| A | B | C | D | E | |

| MBT | 0.5 | 1.5 | 1.5 | 2 | 1.5 |

| TMT | 1.5 | 0.8 | 1 | 0.8 | 0.8 |

| ZDC | - | - | - | 0.8 | - |

| ZDBC | - | 2.5 | 2.5 | 1 | - |

| CBS | - | - | 1 | - | - |

| TeDEDC | - | - | 1 | - | 0.8 |

| DPTTS | - | - | - | - | 0.8 |

| Sulphur | 1.5 | 2 | 1.8 | 2 | 0.5 |

| Cure System | Characteristics | ||||

| A | Low cost, Medium cure rate, Satisfactory vulcanizate properties, may bloom. | ||||

| B | General purpose, Very good cure rate and vulcanizate properties, Non-blooming. | ||||

| C | Low compression set, Faster cure rate, Good vulcanizate properties, Non-blooming. | ||||

| D | Low cost, faster cure rate, Good vulcanizate properties, Non-blooming. | ||||

| E | General purpose, Very fast cure rate and excellent vulcanizate properties, Non-blooming but scorchy. | ||||

Pilflex CBC (促进剂)

- 产品特性

- 产品特性(续)

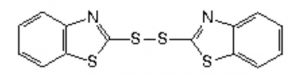

| Chemical Structure | 2-2'-Dithiobis(benzothiazole) (MBTS) | |

| Chemical Structure |

|

|

| CAS Reg. No. | 120-78-5 | |

| Mol. Wt. | 332 | |

| Product Specification | ||

| Parameter | Limits | Test Method |

| Product form | Powder (OT) | - |

| Color | Cream | - |

| Assay (titration ) ,% (min) | 94 | D 5051 |

| Free MBT, % (max) | 1 | D 5044 |

| Melting Point (Initial), °C (min) | 170 | D 1519 |

| Melting Point (Final), °C | 172-179 | D 1519 |

| Heat Loss, % (max) | 0.4 | D 4571 |

| Ash, % (max) | 0.5 | D 4574 |

| Paraffinic Oil (<0.2% PCAH), % | 1.0-2.0 | NOCIL G-40 |

| Residue on 150 µ, % (max) | 0.05 | D 5461 |

| Residue on 63 µ, % (max) | 0.3 | D 5461 |

| Typical Data | ||

| Specific gravity at 25°C | 1.54 | D 1817 |

| Bulk density, kg/m3 | 350 - 390 | NOCIL G-44 |

| Bulk density (Comp), kg/m3 | 420 - 460 | NOCIL G-44 |

| Product Information | ||

| Solubility | Soluble in chloroform. Slightly soluble in acetone and carbon tetra chloride. Insoluble in water. | |

| Classification | Semi ultra fast accelerator. | |

| Discoloration & Staining | Non-discoloring and Non-staining. | |

| FDA Approval Status | Regulated for use in articles in contact with food under FDA 21 CFR 177.2600, 175.105 and BgVV XXI, Categories 1-4. | |

| Toxicity Data (Please refer to the latest, Toxicological information.) | Practically non-harmful. (Oral LD50rat over 5000 mg/kg). Not a skin or eye irritant. | |

| Handling & Personal Protection | Ensure good ventilation and avoid creating dusty atmosphere. In case of eye or skin contacts wash out with clean water for 5 to 10 minutes. | |

| Storage | Store at room temperature in a cool, dry and well ventilated place. Avoid exposure of the packaged material / product to direct sunlight & heat. | |

| Packaging | ||

| Paper / Paper – Fabric Bag | 20 kg | |

| FIBC | 500 kg | |

| Storage Life | 36 months | |

| Color code | Red colored strip. | |

| TYPICAL DOSAGES OF PILCURE MBTS | |||||||

| Product | Rubber | Accelerator / Sulphur, phr | |||||

| MBTS | MBT | MOR | TMTD | ZDEC | S | ||

| Motor Cycle, Scooter | NR- | 1.0-1.2** | - | - | 0.1-0.2 | - | 2.2-2.75* |

| Tyre Treads | SBR / BR | ||||||

| Auto Tubes | IIR | 0.3-0.4 | - | - | 1 | 0.0-0.2 | 1.5 |

| BIIR | 0.5 | - | 0.1 | 0.5 | |||

| Cycle Tyre Treads Casing | NR-RR | 0.8-1.0** | - | - | 0.1-0.2 | - | 2.2-2.5 |

| NR-BR | 1.0-1.2** | 0.1-0.2 | 2.2 | ||||

| NR | 1.0-1.2** | 0.2-0.3 | 2.5-3.0 | ||||

| Conveyor Belt Cover | NR | 0.80** | 0.2 | - | 0.0-0.15 | - | 2.75* |

| SBR | 1.2-1.5** | - | 0.1-0.20 | 2 | |||

| Transmission Belts | NR | 0.3 | - | 0.8 | - | - | 3 |

| General Purpose | NR | 0.4 | - | 2.0-2.5 | 0.3 | ||

| Heat Resistant | |||||||

| V Belts | NR | 0.2 | - | 0.6** | - | - | 3 |

| Base | NR | 0.4 | 0.6** | 2.4 | |||

| Cushion | |||||||

| Retreading Materials | NR | 0.2 | - | 0.7** | - | - | 2.4* |

| Cushion-Hot Cure | NR | 0.6 | 0.4 | - | TMTM-0.2 | 2.4* | |

| Cushion-Cold Cure | NR | 1.2 | - | - | - | 4.0* | |

| Vulcanizing Solution | |||||||

| Footwear | NR-SBR | 0.7 | 0.3 | - | 0.1-0.2 | - | 2.2 |

| DV Soles | NR-SBR | 0.6 | - | 0.1-0.2 | 2.2 | ||

| Microcellular Soles | NR-SBR | 0.7 | 0.3 | 0.1-0.2 | 2.5 | ||

| Neolite Soles | |||||||

| Hot Air Cured Products | NR | 0.4 | 0.4 | - | - | 0.3 | 2.5 |

| Rubberized Fabric and | |||||||

| Rubber Sheeting | |||||||

| Cables | NR | 1 | - | - | TMTM | - | 1.2 |

| SBR | 1.6 | 0.3 | 1 | ||||

| Misc. Molded and | NR | 0.8-1.0 | - | - | 0.0-0.2 | ZDBC 1.5 | 2.4 |

| Extruded Products | SBR | 1.2-1.5 | 0.0-0.2 | 2.2 | |||

| NBR | 1.2-1.5 | 0.0-0.2 | 1.5 | ||||

| EPDM | 3 | 0.75 | 0.5 | ||||

| Pilcure MBTS is also used in following compounds / products | |||||||

| Chlorobutyl Inner Liner (Bias Tyres) : MBTS-0.75 + Alkyl phenol disulfide-1.2 + ZnO-5.0 | |||||||

| Bromobutyl Inner Liner (Radials): MBTS-1.25 + ZnO-3.0 + S-0.4 | |||||||

| Bromobutyl OTR Tubes: MBTS-1.2 + TMTD-1.7 + ZnO-4.0 | |||||||

| Bromobutyl Tank Lining: MBTS-1.0 + TMTD-0.5 + ZnO-5.0 + S-0.5 | |||||||

| Note: | |||||||

| * Insoluble Sulphur (100% active content basis) | |||||||

| ** Pre Vulcanization Inhibitor may be incorporated at 0.2-0.5 phr levels for desired | |||||||

| scorch safety, ensuring compliance with vulcanizate properties. | |||||||

Pilflex CBS (促进剂)

- 产品特性

- 产品特性(续)

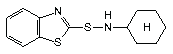

| Chemical Name | N-cyclohexyl-2-benzothiazolesulfenamide (CBS) | |||

| Chemical Structure |

|

|||

| CAS Reg. No. | 95-33-0 | |||

| Mol. Wt. | 264 | |||

| Product Specification | ||||

| Parameter | Limits | |||

| Product form | Pellets (4mm ) | Powder (OT) | - | |

| Color | Off white - cream | Off white - cream | - | |

| Assay (titration ) ,% (min) | 96 | 95 | D 4936 | |

| Melting Point, initial, °C (min) | 97 | 96 | D 1519 | |

| Melting point , final , °C | 99-105 | 98-105 | D 1519 | |

| Heat Loss, % (max) | 0.3 | 0.3 | D 4571 | |

| Methanol Insolubles , % (max) | 0.4 | 0.4 | D 4934 | |

| Free Amine, % (max) | 0.5 | 0.5 | D 4936 | |

| Ash, % (max) | 0.3 | 0.3 | D 4574 | |

| Paraffinic Oil (<0.2% PCAH), % | Not applicable | 1.0-2.0 | NOCIL 02-3-343 | |

| Residue on 150 µm sieve, % (max) | Not applicable | 0.05 | D 5461 | |

| Residue on 63 µm sieve, % (max) | Not applicable | 0.5 | D 5461 | |

| Typical Data | ||||

| Specific gravity at 25°C | 1.27 | D 1817 | ||

| Bulk density , kg/m3 | 450 - 490 410 - 450 | NOCIL G-44 | ||

| Bulk density (Comp), kg/m3 | 480 - 520 540 - 580 | NOCIL G-44 | ||

| Product Information | ||||

| Solubility | Soluble in acetone, benzene, naptha, carbon tetrachloride & ethyl acetate. Partially soluble in ethyl / methyl alcohol. Insoluble in water. | |||

| Classification | Fast - Delayed action accelerator. | |||

| Discoloration & Staining | Non staining. At higher dosages slight discoloration. | |||

| FDA Approval Status | Regulated for use in articles in contact with food under FDA 21 CFR 177.2600, and BgVV XXI, Category 4. | |||

| Toxicity Data (Please refer to the latest Toxicological information.) | Practically non-harmful. (Oral LD50rat over 5000 mg/kg). Not a skin or eye irritant. | |||

| Handling & Personal Protection | Ensure good ventilation and avoid creating dusty atmosphere. In case of eye or skin contacts wash out with clean water for 5 to 10 minutes. | |||

| Storage | Always store in a cool (below 30ºC) & dry place in single stack pallets away from direct sun light or any other heat source to avoid compaction. Avoid exposure to acids, acidic materials / atmosphere & high humidity. | |||

| Packaging | ||||

| Paper-Fabric Bag | 20 kg | |||

| FIBC | 500 kg | |||

| Storage Life | 12 months when stored as stated above. | |||

| Color code | Dark Green colored strip. | |||

| TYPICAL DOSAGES OF PILCURE CBS | |||||||

| Product | Rubber | Accelerator / Sulphur, phr | |||||

| CBS | MBTS | TMTD | TMTM | PVI (CTP) | S | ||

| Auto Tyres | NR | 0.5-0.7 | - | - | - | 0.10-0.15 | 2.4* |

| Treads Casing | NR-BR | 1.2 | - | - | 0-0.25 | 0.10-0.15 | 1.5* |

| SBR-BR | 1.4 | - | - | 0-0.25 | 0.10-0.20 | 1.7* | |

| NR-SBR | 0.8 | - | - | 0-0.10 | 0.10-0.15 | 2.0* | |

| NR | 0.7-0.8 | - | - | 0-0.20 | 0.15-0.20 | 2.4* | |

| NR-SBR | 1 | - | - | 0-0.20 | 0.15-0.20 | 2.2* | |

| NR-BR | 1.0-1.2 | - | - | 0-0.10 | 0.15-0.20 | 2.2* | |

| Cycle Tyre | NR-RR | 1 | - | 0.1-0.15 | - | 0.1-0.2 | 2.4 |

| Treads | NR-SR | 1.2 | - | 0.15-0.2 | - | 0.1-0.2 | 2 |

| Conveyor Belt Cover | NR | 0.7 | 0.2 | - | - | 0.15 | 2.4 |

| General Purpose Heat Resistant | NR-SBR | 1.2 | - | - | - | 0.15 | 1.75 |

| NR-SBR | 1.5 | - | 0.5 | - | 0.25 | 0.5 | |

| Transmission Belts | NR | 0.8 | - | 0.1 | - | 0.15 | 3 |

| V Belts | NR | 0.6 | 0.2 | - | - | 0.2 | 3 |

| Base | NR | 0.75 | 0.1 | - | - | 0.15 | 2.4 |

| Cushion | NR | 0.7 | - | - | - | 0.1 | 2.75 |

| Friction | |||||||

| Retreads (Truck Tyres) | NR | 0.6 | - | - | - | 0.2 | 2.4* |

| Hot Cure Pre Cured | NR-BR | 0.9 | - | - | - | 0.15 | 1.7* |

| Cushion- Hot Cure | NR-BR | 0.9 | 0.3 | - | - | 0.1 | 1.6 |

| NR | 0.7 | - | - | - | 0.15 | 2.5* | |

| Footwear | NR-SBR | 1 | 0.3 | 0.1 | - | 0.1 | 2 |

| DV Soles | NR-SBR | 1 | - | 0.2-0.3 | - | 0.1 | 2.2 |

| Molded Soles & Heels | |||||||

| Hoses | NR | 0.8-1.0 | - | 0.1 | - | 0.1 | 2.2 |

| Tube Cover | NR-SR | 1.0-1.2 | - | 0.2 | - | 0.1 | 1.5 |

| NBR | 1.5 | - | 0.5 | - | 0.1 | 0.7 | |

| NBR | 0.7 | - | 0.1 | - | 0.15 | 1.8 | |

| NR | 0.8 | - | 0.1 | - | 0.15 | 2.2 | |

| Cables | NR | 1 | - | 0.2 | ZDC-0.2 | 0.15 | 1.2 |

| Injection Moldings | NR | 0.6 | - | - | - | 0.3 | 2.4 |

| Molded & Extruded Goods | NR | 0.7 | - | 0.15 | - | 0.1 | 2.2 |

| NR-SeEV | 1.5 | - | 0.5 | - | 0.1 | 1.4 | |

| NR-EV | 3 | - | - | - | - | 0.5 | |

| SBR | 1 | - | 0.2 | - | 0.1 | 2.2 | |

| SBR-SeEV | 2.0 1.5 | - - | 0.50 3.0 | - - | 0.10 0.20 | 0.75 0.30 | |

| SBR-EV | 1 | - | 0.15 | - | 0.1 | 1.5 | |

| NBR | 1.0 2.0 | - - | 1.0 3.0 | - - | - - | 1.0 0.3 | |

| NBR-SeEV | |||||||

| NBR-EV | |||||||

| Note: * Insoluble Sulphur (100% active content basis) | |||||||

Pilcure TMT (促进剂)

- 产品特性

- 产品特性(续)

| Chemical Name | Tetramethyl thiuram disulfide (TMTD) | |

| Chemical Structure |

|

|

| CAS Reg. No. | 137-26-8 | |

| Mol. Wt. | 240 | |

| Product Specification | ||

| Parameter | Limits | Test Method |

| Product form | Powder (OT) | - |

| Color | Off white-Cream | - |

| Assay ,% (min) | 96 | NOCIL 02-3-318 |

| Melting Point, initial, °C | 142 | D 1519 |

| Melting point, final, °C (min) | 147 | D 1519 |

| Heat Loss, % (max) | 0.5 | D 4571 |

| Ash, % (max) | 0.3 | D 4574 |

| Paraffinic Oil (<0.2% PCAH), % | 1.0-2.0 | NOCIL G-40 |

| Residue on 150 µm sieve, % (max) | 0 | D 5461 |

| Residue on 63 µm sieve, % (max) | 0.3 | D 5461 |

| Typical Data | ||

| Specific gravity at 25°C | 1.43 | D 1817 |

| Bulk density , kg/m3 | 340 – 380 | NOCIL G-44 |

| Bulk density (Comp), kg/m3 | 410 - 440 | NOCIL G-44 |

| Product Information | ||

| Solubility | Soluble in methyl chloride, partly soluble in alcohol . Insoluble in water. | |

| Classification | Ultra fast accelerator. | |

| Discoloration & Staining | Non-discoloring and Non-staining. | |

| FDA Approval Status | Regulated for use in articles in contact with food under FDA 21 CFR 177.2600, 175.105, and BgVV XXI categories 1-4 & ‘Sonderkategorie’. | |

| Toxicity Data (Please refer to the latest Toxicological information.) | Harmful by mouth. (Oral LD50rat 780-1300 mg/kg). A substance of moderate toxicity, slight eye & skin irritant and skin sensitizer. Can cause alcohol intolerance by inhalation of dust or absorption through skin. | |

| Handling & Personal Protection | Ensure good ventilation and avoid creating dusty atmosphere. In case of eye or skin contact wash out with clean water for 5 to 10 minutes and seek medical advice urgently if swallowed. | |

| Storage | Always store in a cool (below 35ºC) & dry place in single stack pallets away from direct sun light or any other heat source to avoid grit formation. | |

| Packaging | ||

| Paper-Fabric Bag | 20 kg | |

| FIBC | ||

| Storage Life | 24 months | |

| Color code | Orange colored strip. | |

| TYPICAL DOSAGES OF PILCURE TMT | ||||||||

| Product | Rubber | Accelerator / Sulphur, phr | ||||||

| TMTD | MBTS | CBS | ZDC | ZDBC | DPG | S | ||

| Auto Tubes | Butyl | 1.0-2.0 | 0.3-0.4 | - | 0.2 | - | - | 1.5-2.0 |

| NR | 2.0-2.5 | 1.0-1.3 | - | - | - | - | 0.5 | |

| OTR Tubes | Bromo- Butyl | 1.7 | 1.2 | - | - | - | - | ZnO-4.0 |

| Cycle Tyre : | ||||||||

| Treads | NR | 0.1-0.2 | - | 0.8-1.0 | - | - | - | 2.4 |

| Casing | NR-BR | 0.2 | - | 1.0-1.2 | - | - | - | 1.8-2.0 |

| NR | 0.2-0.3 | 1 | - | - | - | - | 2.5 | |

| NR | 0.05 | 0.7 | - | - | - | 0.25 | 2.5 | |

| Cycle Tubes | NR | 0.1-0.2 | - | 0.8-1.0 | - | - | - | 1.5-1.7 |

| Molded& Extruded Goods | ||||||||

| Conventional Cure | NR | 0.5-0.7 | - | 0.3 | - | - | - | 2.0-2.5 |

| NR | 0.1-0.2 | 0.7-1.0 | - | - | - | - | 2.0-2.5 | |

| NR | 0.1-0.2 | - | 0.7-1.0 | - | - | - | 2.0-2.5 | |

| SBR | 0.1-0.2 | 1.2-1.4 | - | - | - | - | 2.0-2.2 | |

| SBR | 0.1-0.2 | - | 1.0-1.2 | - | - | - | 2.0-2.2 | |

| NBR | 0.2-0.4 | 1.0-1.2 | - | - | - | - | 1.5 | |

| NBR | 0.2-0.4 | - | 1.2-1.4 | - | - | - | 1.5 | |

| Semi EV Cure | EPDM | 1.5 | 0.5 | - | - | - | - | 1.5 |

| EPDM | 0.8 | 2 | - | 0.8 | 1 | - | 2 | |

| EV Cure | EPDM | 0.8 | 1.5 | - | - | 2.5 | - | 2 |

| NR | 0.5 | - | 1.5 | - | - | - | 1.4 | |

| SBR | 0.5 | - | 2 | - | - | - | 0.75 | |

| NBR | 1.5 | - | 1.0-1.2 | - | - | - | 1 | |

| NR | 2.5-3.0 | - | 1.0-1.5 | - | - | - | 0-0.3 | |

| SBR | 3.0-4.0 | - | 1.0-1.2 | - | - | - | 0-0.3 | |

| NBR | 3.0-4.5 | - | 1.0-1.2 | - | - | - | 0-0.3 | |

| Fast Curing Ebonite | NR/ SBR / NBR | 3.0-4.0 | - | - | - | - | - | 20-40 |

| Food Contact Products | NR/ SBR / NBR | 0.5-0.7 | - | - | 0.2-0.4 | - | - | 1.5-2.0 |

补强剂

特征理化数据

特徵理化數據

| Properties and test methods | Unit | Value |

|---|---|---|

| Specific surface area (BET) | m2/g | 175 - 225 |

| pH value in 4% dispersion | 3.7 - 4.5 | |

| Loss on drying* 2 hours at 105 °C | % | ≤ 1.5 |

| Tamped density* | g/l | approx. 50 |

| SiO2 content based on ignited material | % | > 99.8 |

| * explant | ||

| The data represents typical values (no product specification) | ||

AEROSIL® 200 V

注册(物质或产品组件)

| CAS- No. | 112 945- 52- 5 |

| 7631- 86- 9 | |

| REACH (Europe) | registered |

| TSCA (USA) | registered |

| DSL (Canada) | registered |

| AICS (Australia) | registered |

| ENCS (Japan) | registered |

| IECSC (China) | registered |

| KECI (Korea) | registered |

增塑剂

Mesamoll®

化学成分

烷基磺酸苯酯 (ASE)

CAS注册号

91082-17-6 (ASE)

物理形态

微黄色透明液体

健康和安全信息

相关的安全数据和参考数据以及可能需要的警告标签可在第 3 号安全数据表中找到。033204。

根据 GefStoffV 的适应症

根据德国危险货物运输条例、德国危险物质条例 (GefStoffV) 或相应的欧盟指令,Mesamoll 不受卷标限制。

指定属性

| Property | Nominal Value | Unit | Test Method |

|---|---|---|---|

| Refractive index nD 20 | 1.499 ± 0.003 | DIN EN ISO 6320 (method based on) | |

| Acid value | 0.1 max. | mg KOH/g | DIN ISO 2114 |

| Hazen colour value | 400 max. | DIN ISO 6271 | |

| Density at 20 °C | 1.055 ± 0.015 | g/cm3 | DIN 51 757 |

| Viscosity at 20 °C | 115 ± 15 | mPa s | DIN 53 015 |

| Water content | 0.05 max. | % | DIN 51 777 |

附加信息

| Property | Typical Value | Unit | Test Method |

|---|---|---|---|

| Saponification number | only partial saponification possible | mg KOH/g | DIN 53 401 |

| Pour point | approx. -32 | °C | ISO 3016 |

| Flash point (open cup) | approx. 225 | °C | ISO 2592 |

| Dissolution temperature | approx. 116 | °C | DIN 53 408 (method based on) |

增塑剂LN

描述:

一种加氢处理的低粘度环烷橡胶加工油。

典型物理特性:

Weight, lbs./gal ………………………………………………………7.543

Specific Gravity ………………………………………………………0.9045

Color, ASTM 1500 ………………………………………….….…….< 0.5

Viscosity, SUS @ 100°F …………………………………………….106

Viscosity, SUS @ 210°F ……………………………………………37.9

Pour Point, °F………………………………………………………….-40

Flash, C.O.C. °F……………………………………………………….340

Aniline Point, °F (°C) ………………………………………………163 (73)

Refractive Index @ 70°F ………………………………………….1.4945

PAC (polyaromatic content) per method IP346……………<3%

粘土凝胶分析,重量百分比 - D2007:

Asphaltenes ………………………………………………………… < 0.1

Polar Compounds………………………………………………….. 0.6

Aromatics……………………………………………………………. 32.8

Saturates…………………………………………………………….. 66.6

碳类型分析,% - D2140:

Aromatic Carbon Atoms, Ca …………………………………….10

Naphthenic Carbon Atoms, Cn …………………………………46

Paraffinic Carbon Atoms, Cp…………………………………….44