Rubber Chemical

PILFLEX 13

- Product Properties

- Product Properties (cont.)

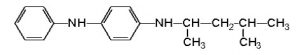

| Chemical Name | N-(1,3-dimethylbutyl)-N’-phenyl-p-phenylenediamine. (6PPD) | |

|---|---|---|

| Chemical Structure |

|

|

| CAS Reg. No. | 793-24-8 | |

| Mol. Wt. | 268 | |

| Product Specification | ||

| Parameter | Limits | Test Method |

| Product form | Pastilles | - |

| Color | Dark purple | - |

| Assay (Titration), % (min) | 97 | D 4937 |

| Melting Point (Initial), °C (min) | 46 | D 1519 |

| Melting Point (Final), °C | 48-51 | D 1519 |

| Heat Loss, % (max) | 0.3 | D 4571 |

| Ash, % (max) | 0.1 | D 4574 |

| Typical Data | ||

| Viscosity @ 60 °C, cps | 27-38 | NOCIL G-5 |

| Specific gravity at 60°C. | 0.986-1.00 | NOCIL G-25 |

| Bulk density , kg/m3 | 550 - 590 | NOCIL G-44 |

| Product Information | ||

| Solubility | Soluble in acetone and ethyl alcohol; moderately soluble in hydrocarbon solvents. Insoluble in water. | |

| Classification | High activity Antidegradant. | |

| Discoloration & Staining | Discolors white / colored products. Contact / Migration staining is experienced on other surfaces in contact with rubber products containing 6PPD. | |

| FDA Approval Status | Regulated for use in articles in contact with food under BgVV XXI, Category 3-4. Not regulated for use in articles in contact with food under FDA. | |

| Toxicity Data (Please refer to the latest Toxicological information.) | Slightly harmful by mouth. (Oral LD50rat 2500-3340 mg/kg). Not a skin or eye irritant. Unlikely to cause skin sensitization in man except individuals sensitized by other para phenylenediamines. | |

| Handling & Personal Protection | Ensure good ventilation and avoid creating dusty atmosphere. In case of eye or skin contacts wash out with clean water for 5 to 10 minutes. | |

| Storage | Always store in a cool (below 30ºC) & dry place in single stack pallets away from direct sun light or any other heat source to avoid compaction. | |

| Packaging | ||

| Paper Bag / Drum | Paper Bag: 20 kg / Fiber board drum: 50 kg. | |

| FIBC | 500 kg / 800 kg | |

| Storage Life | 12 months when stored as stated above. | |

| Color code | Green colored strip. | |

| TYPICAL DOSAGES OF PILFLex 13 | |||

|---|---|---|---|

| Product | Antioxidant / Antiozonant / Wax , phr | ||

| Rubber | Pilflex 13 | Pilnox TDQ | |

| Truck Tyres | NR-BR | 2.5-3.5 | 1 |

| Treads (Cross ply, Front Tyres) | NR | 3.0-3.5 | 1 |

| Treads (Cross ply, Rear Tyres) | NR-BR | 3.0-3.5 | 1 |

| Treads (Radials) | NR-BR | 2.7-3.0 | 1 |

| Sidewall (Cross ply) | NR-BR | 3.0-4.0 | 1 |

| Sidewall (Radials) | NR | 0.7-1.0 | 1 |

| Carcass (Cross ply) | NR | 0.7-1.0 | 1 |

| Carcass (Radial) | |||

| Passenger Tyres (Radials) | NR-SBR-BR | 2.5-3.0 | 1 |

| Tread | SBR-BR | 2.5-3.0 | 1 |

| Sidewall | NR-BR | 3.0-3.5 | 1 |

| Carcass | NR/ NR-SBR | 0.5 | 1 |

| Motor cycle / Scooter Tyres | SBR-BR | 1.75-2.0 | 1 |

| Tread | NR-SBR | 0.5 | 1 |

| Carcass | |||

| Auto Tubes | IIR | 0.5 | - |

| NR | 1 | 1 | |

| Flaps | NR/ NR-RR | 0.5 | 1 |

| Bicycle Tyre Treads | NR-RR | 0.5 | 1 |

| NR-BR-RR | 0.5 | 1 | |

| Bicycle Tubes | NR | 0.5 | 1 |

| Cycle Tyre curing bags | NR | 1 | 1.5-2.0 |

| Retreads | NR/NR-BR | 0.5-0.75 | 1 |

| Hot cure | NR-BR | 1 | 1 |

| Cold cure | SBR-BR | 1 | 1 |

| Cushion gum | NR | - | 1 |

| Conveyor belt cover | NR | 1.0-1.5 | 1.0-1.5 |

| NR-SBR | 1.0-1.5 | 1.0-1.5 | |

| V belts | NR | 1 | 1 |

| Base | NR | 0.5 | 1 |

| Cushion | |||

| Molded & Extruded goods | NR/NR-SBR | 0.5-1.0 | 1 |

| NBR | 0.5-1.0 | 1 | |

| * Paraffin wax may be used | |||

PILFLEX MBT

- Product Properties

- Product Properties (cont.)

- Product Properties (cont.)

| Chemical Name | 2-mercaptobenzothiazole (MBT) | |

|---|---|---|

| Chemical Structure |

|

|

| CAS Reg. No. | 149-30-4 | |

| Mol. Wt. | 167 | |

| Product Specification | ||

| Parameter | Limits | Test Method |

| Product form | Powder (OT) | - |

| Color | Cream | - |

| Assay (Titration), % (min) | 96 | D 1991 |

| Melting Point (Initial), °C (min) | 170 | D 1519 |

| Melting Point (Final), °C | 176-183 | D 1519 |

| Heat Loss, % (max) | 0.4 | D 4571 |

| Ash, % (max) | 0.4 | D 4574 |

| Paraffinic Oil (<0.2% PCAH), % | 1.0-2.0 | NOCIL G-40 |

| Residue on 150 µm sieve, % (max) | 0.05 | D 5461 |

| Residue on 63 µm sieve, % (max) | 0.5 | D 5461 |

| Typical Data | ||

| Specific gravity at 25°C | 1.51 | D 1817 |

| Bulk density, kg/m3 | 400 - 440 | NOCIL G-44 |

| Bulk density (Comp), kg/m3 | 580 - 620 | NOCIL G-44 |

| Product Information | ||

| Solubility | Soluble in acetone, chloroform and dilute alkali. Slightly soluble in alcohol. Insoluble in water and gasoline. | |

| Classification | Semi ultra fast accelerator. | |

| Discoloration & Staining | Non-discoloring and Non-staining. | |

| FDA Approval Status | Regulated for use in articles in contact with food under FDA 21 CFR 177.2600, 175.105, 176.300 and BgVV XXI categories 1-4 & ‘Sonderkategorie’. | |

| Toxicity Data (Please refer to the latest Toxicological information.) | Practically non-harmful. (Oral LD50rat over 5000 mg/kg). Not a skin or eye irritant. | |

| Handling & Personal Protection | Ensure good ventilation and avoid creating dusty atmosphere. In case of eye or skin contacts wash out with clean water for 5 to 10 minutes. | |

| Storage | Store at room temperature in a cool, dry and well ventilated place. Avoid exposure of the packaged material / product to direct sunlight & heat. | |

| Packaging | ||

| Paper-Fabric Bag | 20 kg | |

| FIBC | 500 kg | |

| Storage Life | 24 months | |

| Color code | Blue colored strip. | |

| TYPICAL DOSAGES OF PILCURE MBT | |||||||

|---|---|---|---|---|---|---|---|

| Product | Rubber | Accelerator / Sulphur, phr | |||||

| MBT | MBTS | MOR | TMTD | ZDEC | S | ||

| Motor Cycle, Scooter | NR- | 0.8-1.0** | - | - | 0.07-0.15 | - | 2.2-2.75* |

| Tyre Treads | SBR / BR | ||||||

| Auto Tubes | IIR | 0.5 | - | - | 1 | 0.0-0.2 | 1.5 |

| Cycle Tyre Treads | NR-RR | 0.6** | 0.3 | - | 0.1-0.15 | - | 2.2-2.5 |

| NR-SBR / BR | 0.8** | 0.4 | - | 0.1-0.2 | - | 2.2 | |

| Conveyor Belt Cover | NR | 0.70** | 0.25 | - | 0.0-0.15 | - | 2.75* |

| SBR | 1.0** | 0.4 | - | 0.0-0.20 | - | 2.2 | |

| Transmission Belts | NR | 0.3 | - | 0.8 | - | - | 3.0 |

| General Purpose | NR | 0.5 | - | - | 2.0-2.5 | - | 0.3 |

| Heat Resistant | |||||||

| V Belts | NR | 0.2 | - | 0.6** | - | - | 3.0 |

| Base | NR | 0.4 | - | 0.6** | - | - | 2.4 |

| Cushion | |||||||

| Retreading Materials | NR | 0.2 | - | 0.7** | - | - | 2.4* |

| Cushion-Hot Cure | NR | 1 | - | - | TMTM-0.2 | - | 2.4* |

| Cushion-Cold Cure | NR | 0.6 | 0.4 | - | - | - | 4.0* |

| Vulcanizing Solution | |||||||

| Footwear | NR-SBR | 0.8 | - | - | 0.2-0.3 | - | 2.0 |

| DV Soles | NR-SBR | 1 | 0.1-0.2 | 2.3 | |||

| Microcellular Soles | NR-SBR | 1 | 0.1-0.2 | 2.5 | |||

| Neolite Soles | |||||||

| Hot Air Cured Products | NR | 0.8 | - | - | - | 0.3-0.4 | 2.5 |

| Rubberized Fabric and Rubber Sheeting | |||||||

| Cables | NR | 1 | - | - | TMTM | - | 1.2 |

| SBR | 1.5 | 0.2-0.3 | 1 | ||||

| Misc. Molded and Extruded Products | NR | 0.8-1.0 | - | - | 0.0-0.2 | - | 2.4 |

| SBR | 1.2-1.5 | 2.2 | |||||

| NBR | 1.2-1.5 | 1.5 | |||||

| Note: | |||||||

| * Insoluble Sulphur (100% active content basis) | |||||||

| ** Pre Vulcanization Inhibitor may be incorporated at 0.2-0.5 phr levels for desired | |||||||

| scorch safety, ensuring compliance with vulcanizate properties. | |||||||

| PILCURE MBT based Cure Systems for sulphur cured EPDM Products | |||||

| Accelerator & Sulphur | Cure Systems (phr) | ||||

| A | B | C | D | E | |

| MBT | 0.5 | 1.5 | 1.5 | 2 | 1.5 |

| TMT | 1.5 | 0.8 | 1 | 0.8 | 0.8 |

| ZDC | - | - | - | 0.8 | - |

| ZDBC | - | 2.5 | 2.5 | 1 | - |

| CBS | - | - | 1 | - | - |

| TeDEDC | - | - | 1 | - | 0.8 |

| DPTTS | - | - | - | - | 0.8 |

| Sulphur | 1.5 | 2 | 1.8 | 2 | 0.5 |

| Cure System | Characteristics | ||||

| A | Low cost, Medium cure rate, Satisfactory vulcanizate properties, may bloom. | ||||

| B | General purpose, Very good cure rate and vulcanizate properties, Non-blooming. | ||||

| C | Low compression set, Faster cure rate, Good vulcanizate properties, Non-blooming. | ||||

| D | Low cost, faster cure rate, Good vulcanizate properties, Non-blooming. | ||||

| E | General purpose, Very fast cure rate and excellent vulcanizate properties, Non-blooming but scorchy. | ||||

PILCURE MBTS

- Product Properties

- Product Properties (cont.)

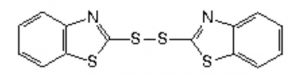

| Chemical Structure | 2-2'-Dithiobis(benzothiazole) (MBTS) | |

| Chemical Structure |

|

|

| CAS Reg. No. | 120-78-5 | |

| Mol. Wt. | 332 | |

| Product Specification | ||

| Parameter | Limits | Test Method |

| Product form | Powder (OT) | - |

| Color | Cream | - |

| Assay (titration ) ,% (min) | 94 | D 5051 |

| Free MBT, % (max) | 1 | D 5044 |

| Melting Point (Initial), °C (min) | 170 | D 1519 |

| Melting Point (Final), °C | 172-179 | D 1519 |

| Heat Loss, % (max) | 0.4 | D 4571 |

| Ash, % (max) | 0.5 | D 4574 |

| Paraffinic Oil (<0.2% PCAH), % | 1.0-2.0 | NOCIL G-40 |

| Residue on 150 µ, % (max) | 0.05 | D 5461 |

| Residue on 63 µ, % (max) | 0.3 | D 5461 |

| Typical Data | ||

| Specific gravity at 25°C | 1.54 | D 1817 |

| Bulk density, kg/m3 | 350 - 390 | NOCIL G-44 |

| Bulk density (Comp), kg/m3 | 420 - 460 | NOCIL G-44 |

| Product Information | ||

| Solubility | Soluble in chloroform. Slightly soluble in acetone and carbon tetra chloride. Insoluble in water. | |

| Classification | Semi ultra fast accelerator. | |

| Discoloration & Staining | Non-discoloring and Non-staining. | |

| FDA Approval Status | Regulated for use in articles in contact with food under FDA 21 CFR 177.2600, 175.105 and BgVV XXI, Categories 1-4. | |

| Toxicity Data (Please refer to the latest, Toxicological information.) | Practically non-harmful. (Oral LD50rat over 5000 mg/kg). Not a skin or eye irritant. | |

| Handling & Personal Protection | Ensure good ventilation and avoid creating dusty atmosphere. In case of eye or skin contacts wash out with clean water for 5 to 10 minutes. | |

| Storage | Store at room temperature in a cool, dry and well ventilated place. Avoid exposure of the packaged material / product to direct sunlight & heat. | |

| Packaging | ||

| Paper / Paper – Fabric Bag | 20 kg | |

| FIBC | 500 kg | |

| Storage Life | 36 months | |

| Color code | Red colored strip. | |

| TYPICAL DOSAGES OF PILCURE MBTS | |||||||

| Product | Rubber | Accelerator / Sulphur, phr | |||||

| MBTS | MBT | MOR | TMTD | ZDEC | S | ||

| Motor Cycle, Scooter | NR- | 1.0-1.2** | - | - | 0.1-0.2 | - | 2.2-2.75* |

| Tyre Treads | SBR / BR | ||||||

| Auto Tubes | IIR | 0.3-0.4 | - | - | 1 | 0.0-0.2 | 1.5 |

| BIIR | 0.5 | - | 0.1 | 0.5 | |||

| Cycle Tyre Treads Casing | NR-RR | 0.8-1.0** | - | - | 0.1-0.2 | - | 2.2-2.5 |

| NR-BR | 1.0-1.2** | 0.1-0.2 | 2.2 | ||||

| NR | 1.0-1.2** | 0.2-0.3 | 2.5-3.0 | ||||

| Conveyor Belt Cover | NR | 0.80** | 0.2 | - | 0.0-0.15 | - | 2.75* |

| SBR | 1.2-1.5** | - | 0.1-0.20 | 2 | |||

| Transmission Belts | NR | 0.3 | - | 0.8 | - | - | 3 |

| General Purpose | NR | 0.4 | - | 2.0-2.5 | 0.3 | ||

| Heat Resistant | |||||||

| V Belts | NR | 0.2 | - | 0.6** | - | - | 3 |

| Base | NR | 0.4 | 0.6** | 2.4 | |||

| Cushion | |||||||

| Retreading Materials | NR | 0.2 | - | 0.7** | - | - | 2.4* |

| Cushion-Hot Cure | NR | 0.6 | 0.4 | - | TMTM-0.2 | 2.4* | |

| Cushion-Cold Cure | NR | 1.2 | - | - | - | 4.0* | |

| Vulcanizing Solution | |||||||

| Footwear | NR-SBR | 0.7 | 0.3 | - | 0.1-0.2 | - | 2.2 |

| DV Soles | NR-SBR | 0.6 | - | 0.1-0.2 | 2.2 | ||

| Microcellular Soles | NR-SBR | 0.7 | 0.3 | 0.1-0.2 | 2.5 | ||

| Neolite Soles | |||||||

| Hot Air Cured Products | NR | 0.4 | 0.4 | - | - | 0.3 | 2.5 |

| Rubberized Fabric and | |||||||

| Rubber Sheeting | |||||||

| Cables | NR | 1 | - | - | TMTM | - | 1.2 |

| SBR | 1.6 | 0.3 | 1 | ||||

| Misc. Molded and | NR | 0.8-1.0 | - | - | 0.0-0.2 | ZDBC 1.5 | 2.4 |

| Extruded Products | SBR | 1.2-1.5 | 0.0-0.2 | 2.2 | |||

| NBR | 1.2-1.5 | 0.0-0.2 | 1.5 | ||||

| EPDM | 3 | 0.75 | 0.5 | ||||

| Pilcure MBTS is also used in following compounds / products | |||||||

| Chlorobutyl Inner Liner (Bias Tyres) : MBTS-0.75 + Alkyl phenol disulfide-1.2 + ZnO-5.0 | |||||||

| Bromobutyl Inner Liner (Radials): MBTS-1.25 + ZnO-3.0 + S-0.4 | |||||||

| Bromobutyl OTR Tubes: MBTS-1.2 + TMTD-1.7 + ZnO-4.0 | |||||||

| Bromobutyl Tank Lining: MBTS-1.0 + TMTD-0.5 + ZnO-5.0 + S-0.5 | |||||||

| Note: | |||||||

| * Insoluble Sulphur (100% active content basis) | |||||||

| ** Pre Vulcanization Inhibitor may be incorporated at 0.2-0.5 phr levels for desired | |||||||

| scorch safety, ensuring compliance with vulcanizate properties. | |||||||

PILCURE CBS

- Product Properties

- Product Properties (cont.)

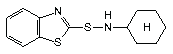

| Chemical Name | N-cyclohexyl-2-benzothiazolesulfenamide (CBS) | |||

| Chemical Structure |

|

|||

| CAS Reg. No. | 95-33-0 | |||

| Mol. Wt. | 264 | |||

| Product Specification | ||||

| Parameter | Limits | |||

| Product form | Pellets (4mm ) | Powder (OT) | - | |

| Color | Off white - cream | Off white - cream | - | |

| Assay (titration ) ,% (min) | 96 | 95 | D 4936 | |

| Melting Point, initial, °C (min) | 97 | 96 | D 1519 | |

| Melting point , final , °C | 99-105 | 98-105 | D 1519 | |

| Heat Loss, % (max) | 0.3 | 0.3 | D 4571 | |

| Methanol Insolubles , % (max) | 0.4 | 0.4 | D 4934 | |

| Free Amine, % (max) | 0.5 | 0.5 | D 4936 | |

| Ash, % (max) | 0.3 | 0.3 | D 4574 | |

| Paraffinic Oil (<0.2% PCAH), % | Not applicable | 1.0-2.0 | NOCIL 02-3-343 | |

| Residue on 150 µm sieve, % (max) | Not applicable | 0.05 | D 5461 | |

| Residue on 63 µm sieve, % (max) | Not applicable | 0.5 | D 5461 | |

| Typical Data | ||||

| Specific gravity at 25°C | 1.27 | D 1817 | ||

| Bulk density , kg/m3 | 450 - 490 410 - 450 | NOCIL G-44 | ||

| Bulk density (Comp), kg/m3 | 480 - 520 540 - 580 | NOCIL G-44 | ||

| Product Information | ||||

| Solubility | Soluble in acetone, benzene, naptha, carbon tetrachloride & ethyl acetate. Partially soluble in ethyl / methyl alcohol. Insoluble in water. | |||

| Classification | Fast - Delayed action accelerator. | |||

| Discoloration & Staining | Non staining. At higher dosages slight discoloration. | |||

| FDA Approval Status | Regulated for use in articles in contact with food under FDA 21 CFR 177.2600, and BgVV XXI, Category 4. | |||

| Toxicity Data (Please refer to the latest Toxicological information.) | Practically non-harmful. (Oral LD50rat over 5000 mg/kg). Not a skin or eye irritant. | |||

| Handling & Personal Protection | Ensure good ventilation and avoid creating dusty atmosphere. In case of eye or skin contacts wash out with clean water for 5 to 10 minutes. | |||

| Storage | Always store in a cool (below 30ºC) & dry place in single stack pallets away from direct sun light or any other heat source to avoid compaction. Avoid exposure to acids, acidic materials / atmosphere & high humidity. | |||

| Packaging | ||||

| Paper-Fabric Bag | 20 kg | |||

| FIBC | 500 kg | |||

| Storage Life | 12 months when stored as stated above. | |||

| Color code | Dark Green colored strip. | |||

| TYPICAL DOSAGES OF PILCURE CBS | |||||||

| Product | Rubber | Accelerator / Sulphur, phr | |||||

| CBS | MBTS | TMTD | TMTM | PVI (CTP) | S | ||

| Auto Tyres | NR | 0.5-0.7 | - | - | - | 0.10-0.15 | 2.4* |

| Treads Casing | NR-BR | 1.2 | - | - | 0-0.25 | 0.10-0.15 | 1.5* |

| SBR-BR | 1.4 | - | - | 0-0.25 | 0.10-0.20 | 1.7* | |

| NR-SBR | 0.8 | - | - | 0-0.10 | 0.10-0.15 | 2.0* | |

| NR | 0.7-0.8 | - | - | 0-0.20 | 0.15-0.20 | 2.4* | |

| NR-SBR | 1 | - | - | 0-0.20 | 0.15-0.20 | 2.2* | |

| NR-BR | 1.0-1.2 | - | - | 0-0.10 | 0.15-0.20 | 2.2* | |

| Cycle Tyre | NR-RR | 1 | - | 0.1-0.15 | - | 0.1-0.2 | 2.4 |

| Treads | NR-SR | 1.2 | - | 0.15-0.2 | - | 0.1-0.2 | 2 |

| Conveyor Belt Cover | NR | 0.7 | 0.2 | - | - | 0.15 | 2.4 |

| General Purpose Heat Resistant | NR-SBR | 1.2 | - | - | - | 0.15 | 1.75 |

| NR-SBR | 1.5 | - | 0.5 | - | 0.25 | 0.5 | |

| Transmission Belts | NR | 0.8 | - | 0.1 | - | 0.15 | 3 |

| V Belts | NR | 0.6 | 0.2 | - | - | 0.2 | 3 |

| Base | NR | 0.75 | 0.1 | - | - | 0.15 | 2.4 |

| Cushion | NR | 0.7 | - | - | - | 0.1 | 2.75 |

| Friction | |||||||

| Retreads (Truck Tyres) | NR | 0.6 | - | - | - | 0.2 | 2.4* |

| Hot Cure Pre Cured | NR-BR | 0.9 | - | - | - | 0.15 | 1.7* |

| Cushion- Hot Cure | NR-BR | 0.9 | 0.3 | - | - | 0.1 | 1.6 |

| NR | 0.7 | - | - | - | 0.15 | 2.5* | |

| Footwear | NR-SBR | 1 | 0.3 | 0.1 | - | 0.1 | 2 |

| DV Soles | NR-SBR | 1 | - | 0.2-0.3 | - | 0.1 | 2.2 |

| Molded Soles & Heels | |||||||

| Hoses | NR | 0.8-1.0 | - | 0.1 | - | 0.1 | 2.2 |

| Tube Cover | NR-SR | 1.0-1.2 | - | 0.2 | - | 0.1 | 1.5 |

| NBR | 1.5 | - | 0.5 | - | 0.1 | 0.7 | |

| NBR | 0.7 | - | 0.1 | - | 0.15 | 1.8 | |

| NR | 0.8 | - | 0.1 | - | 0.15 | 2.2 | |

| Cables | NR | 1 | - | 0.2 | ZDC-0.2 | 0.15 | 1.2 |

| Injection Moldings | NR | 0.6 | - | - | - | 0.3 | 2.4 |

| Molded & Extruded Goods | NR | 0.7 | - | 0.15 | - | 0.1 | 2.2 |

| NR-SeEV | 1.5 | - | 0.5 | - | 0.1 | 1.4 | |

| NR-EV | 3 | - | - | - | - | 0.5 | |

| SBR | 1 | - | 0.2 | - | 0.1 | 2.2 | |

| SBR-SeEV | 2.0 1.5 | - - | 0.50 3.0 | - - | 0.10 0.20 | 0.75 0.30 | |

| SBR-EV | 1 | - | 0.15 | - | 0.1 | 1.5 | |

| NBR | 1.0 2.0 | - - | 1.0 3.0 | - - | - - | 1.0 0.3 | |

| NBR-SeEV | |||||||

| NBR-EV | |||||||

| Note: * Insoluble Sulphur (100% active content basis) | |||||||

PILCURE TMT

- Product Properties

- Product Properties (cont.)

| Chemical Name | Tetramethyl thiuram disulfide (TMTD) | |

| Chemical Structure |

|

|

| CAS Reg. No. | 137-26-8 | |

| Mol. Wt. | 240 | |

| Product Specification | ||

| Parameter | Limits | Test Method |

| Product form | Powder (OT) | - |

| Color | Off white-Cream | - |

| Assay ,% (min) | 96 | NOCIL 02-3-318 |

| Melting Point, initial, °C | 142 | D 1519 |

| Melting point, final, °C (min) | 147 | D 1519 |

| Heat Loss, % (max) | 0.5 | D 4571 |

| Ash, % (max) | 0.3 | D 4574 |

| Paraffinic Oil (<0.2% PCAH), % | 1.0-2.0 | NOCIL G-40 |

| Residue on 150 µm sieve, % (max) | 0 | D 5461 |

| Residue on 63 µm sieve, % (max) | 0.3 | D 5461 |

| Typical Data | ||

| Specific gravity at 25°C | 1.43 | D 1817 |

| Bulk density , kg/m3 | 340 – 380 | NOCIL G-44 |

| Bulk density (Comp), kg/m3 | 410 - 440 | NOCIL G-44 |

| Product Information | ||

| Solubility | Soluble in methyl chloride, partly soluble in alcohol . Insoluble in water. | |

| Classification | Ultra fast accelerator. | |

| Discoloration & Staining | Non-discoloring and Non-staining. | |

| FDA Approval Status | Regulated for use in articles in contact with food under FDA 21 CFR 177.2600, 175.105, and BgVV XXI categories 1-4 & ‘Sonderkategorie’. | |

| Toxicity Data (Please refer to the latest Toxicological information.) | Harmful by mouth. (Oral LD50rat 780-1300 mg/kg). A substance of moderate toxicity, slight eye & skin irritant and skin sensitizer. Can cause alcohol intolerance by inhalation of dust or absorption through skin. | |

| Handling & Personal Protection | Ensure good ventilation and avoid creating dusty atmosphere. In case of eye or skin contact wash out with clean water for 5 to 10 minutes and seek medical advice urgently if swallowed. | |

| Storage | Always store in a cool (below 35ºC) & dry place in single stack pallets away from direct sun light or any other heat source to avoid grit formation. | |

| Packaging | ||

| Paper-Fabric Bag | 20 kg | |

| FIBC | ||

| Storage Life | 24 months | |

| Color code | Orange colored strip. | |

| TYPICAL DOSAGES OF PILCURE TMT | ||||||||

| Product | Rubber | Accelerator / Sulphur, phr | ||||||

| TMTD | MBTS | CBS | ZDC | ZDBC | DPG | S | ||

| Auto Tubes | Butyl | 1.0-2.0 | 0.3-0.4 | - | 0.2 | - | - | 1.5-2.0 |

| NR | 2.0-2.5 | 1.0-1.3 | - | - | - | - | 0.5 | |

| OTR Tubes | Bromo- Butyl | 1.7 | 1.2 | - | - | - | - | ZnO-4.0 |

| Cycle Tyre : | ||||||||

| Treads | NR | 0.1-0.2 | - | 0.8-1.0 | - | - | - | 2.4 |

| Casing | NR-BR | 0.2 | - | 1.0-1.2 | - | - | - | 1.8-2.0 |

| NR | 0.2-0.3 | 1 | - | - | - | - | 2.5 | |

| NR | 0.05 | 0.7 | - | - | - | 0.25 | 2.5 | |

| Cycle Tubes | NR | 0.1-0.2 | - | 0.8-1.0 | - | - | - | 1.5-1.7 |

| Molded& Extruded Goods | ||||||||

| Conventional Cure | NR | 0.5-0.7 | - | 0.3 | - | - | - | 2.0-2.5 |

| NR | 0.1-0.2 | 0.7-1.0 | - | - | - | - | 2.0-2.5 | |

| NR | 0.1-0.2 | - | 0.7-1.0 | - | - | - | 2.0-2.5 | |

| SBR | 0.1-0.2 | 1.2-1.4 | - | - | - | - | 2.0-2.2 | |

| SBR | 0.1-0.2 | - | 1.0-1.2 | - | - | - | 2.0-2.2 | |

| NBR | 0.2-0.4 | 1.0-1.2 | - | - | - | - | 1.5 | |

| NBR | 0.2-0.4 | - | 1.2-1.4 | - | - | - | 1.5 | |

| Semi EV Cure | EPDM | 1.5 | 0.5 | - | - | - | - | 1.5 |

| EPDM | 0.8 | 2 | - | 0.8 | 1 | - | 2 | |

| EV Cure | EPDM | 0.8 | 1.5 | - | - | 2.5 | - | 2 |

| NR | 0.5 | - | 1.5 | - | - | - | 1.4 | |

| SBR | 0.5 | - | 2 | - | - | - | 0.75 | |

| NBR | 1.5 | - | 1.0-1.2 | - | - | - | 1 | |

| NR | 2.5-3.0 | - | 1.0-1.5 | - | - | - | 0-0.3 | |

| SBR | 3.0-4.0 | - | 1.0-1.2 | - | - | - | 0-0.3 | |

| NBR | 3.0-4.5 | - | 1.0-1.2 | - | - | - | 0-0.3 | |

| Fast Curing Ebonite | NR/ SBR / NBR | 3.0-4.0 | - | - | - | - | - | 20-40 |

| Food Contact Products | NR/ SBR / NBR | 0.5-0.7 | - | - | 0.2-0.4 | - | - | 1.5-2.0 |

Reinforcing Agent

AEROSIL® 200 V

Characteristic physico-chemical data

| Properties and test methods | Unit | Value |

|---|---|---|

| Specific surface area (BET) | m2/g | 175 - 225 |

| pH value in 4% dispersion | 3.7 - 4.5 | |

| Loss on drying* 2 hours at 105 °C | % | ≤ 1.5 |

| Tamped density* | g/l | approx. 50 |

| SiO2 content based on ignited material | % | > 99.8 |

| * explant | ||

| The data represents typical values (no product specification) | ||

AEROSIL® 200 V

Registrations (substance or product components)

| CAS- No. | 112 945- 52- 5 |

| 7631- 86- 9 | |

| REACH (Europe) | registered |

| TSCA (USA) | registered |

| DSL (Canada) | registered |

| AICS (Australia) | registered |

| ENCS (Japan) | registered |

| IECSC (China) | registered |

| KECI (Korea) | registered |

Plasticizers

Mesamoll®

Chemical composition

alkylsulphonic phenyl ester (ASE)

CAS Reg. No.

91082-17-6 (ASE)

Physical form

slightly yellowish, clear liquid

Health and safety information

Relevant safety data and references as well as possibly necessary warning labels are to be found in the safety data sheet no. 033204.

Indication according to GefStoffV

Mesamoll is not subject to labelling according to the German Regulations on the Transport of Dangerous Goods, the German Regulation on Dangerous Substances (GefStoffV) or corresponding EU directives.

Specified Properties

| Property | Nominal Value | Unit | Test Method |

|---|---|---|---|

| Refractive index nD 20 | 1.499 ± 0.003 | DIN EN ISO 6320 (method based on) | |

| Acid value | 0.1 max. | mg KOH/g | DIN ISO 2114 |

| Hazen colour value | 400 max. | DIN ISO 6271 | |

| Density at 20 °C | 1.055 ± 0.015 | g/cm3 | DIN 51 757 |

| Viscosity at 20 °C | 115 ± 15 | mPa s | DIN 53 015 |

| Water content | 0.05 max. | % | DIN 51 777 |

Additional Information

| Property | Typical Value | Unit | Test Method |

|---|---|---|---|

| Saponification number | only partial saponification possible | mg KOH/g | DIN 53 401 |

| Pour point | approx. -32 | °C | ISO 3016 |

| Flash point (open cup) | approx. 225 | °C | ISO 2592 |

| Dissolution temperature | approx. 116 | °C | DIN 53 408 (method based on) |

PLASTICIZER LN

DESCRIPTION:

A hydro-treated naphthenic rubber process oil of low viscosity.

TYPICAL PHYSICAL PROPERTIES:

Weight, lbs./gal ………………………………………………………7.543

Specific Gravity ………………………………………………………0.9045

Color, ASTM 1500 ………………………………………….….…….< 0.5

Viscosity, SUS @ 100°F …………………………………………….106

Viscosity, SUS @ 210°F ……………………………………………37.9

Pour Point, °F………………………………………………………….-40

Flash, C.O.C. °F……………………………………………………….340

Aniline Point, °F (°C) ………………………………………………163 (73)

Refractive Index @ 70°F ………………………………………….1.4945

PAC (polyaromatic content) per method IP346……………<3%

CLAY-GEL ANALYSIS, WT % - D2007:

Asphaltenes ………………………………………………………… < 0.1

Polar Compounds………………………………………………….. 0.6

Aromatics……………………………………………………………. 32.8

Saturates…………………………………………………………….. 66.6

CARBON TYPE ANALYSIS, % - D2140:

Aromatic Carbon Atoms, Ca …………………………………….10

Naphthenic Carbon Atoms, Cn …………………………………46

Paraffinic Carbon Atoms, Cp…………………………………….44